Market Growth Projections

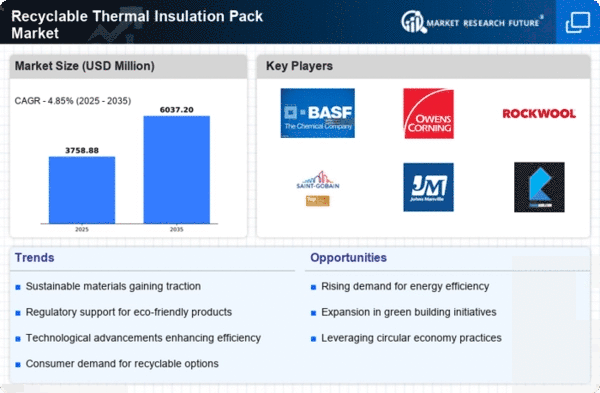

The Global Recyclable Thermal Insulation Pack Market Industry is projected to experience significant growth over the coming years. With a market value expected to reach 3.59 USD Billion in 2024 and further increase to 6.04 USD Billion by 2035, the industry is poised for a robust expansion. The anticipated CAGR of 4.85% from 2025 to 2035 indicates a strong upward trajectory, driven by various factors including sustainability trends, regulatory support, and technological advancements. This growth trajectory suggests a promising future for recyclable thermal insulation packs as they become integral components of sustainable building practices.

Growing Demand for Sustainable Solutions

The Global Recyclable Thermal Insulation Pack Market Industry is witnessing a notable increase in demand for sustainable insulation solutions. As environmental awareness rises, consumers and businesses alike are seeking eco-friendly alternatives to traditional insulation materials. This shift is driven by regulatory pressures and a growing preference for products that minimize environmental impact. The market is projected to reach 3.59 USD Billion in 2024, reflecting a significant trend towards sustainability. Companies that invest in recyclable thermal insulation packs are likely to gain competitive advantages, appealing to a broader customer base that prioritizes sustainability in their purchasing decisions.

Market Penetration in Emerging Economies

Emerging economies are increasingly recognizing the importance of sustainable construction practices, which is positively impacting the Global Recyclable Thermal Insulation Pack Market Industry. As urbanization accelerates in these regions, there is a rising demand for energy-efficient building materials. The adoption of recyclable thermal insulation packs is gaining traction as these countries strive to meet international sustainability standards. This trend is expected to drive market growth, as manufacturers look to penetrate these developing markets. The potential for expansion in emerging economies presents a lucrative opportunity for businesses focused on recyclable insulation solutions.

Rising Energy Costs and Efficiency Awareness

The increasing cost of energy is prompting consumers and businesses to seek more efficient insulation solutions, thereby driving the Global Recyclable Thermal Insulation Pack Market Industry. As energy prices continue to rise, the financial benefits of investing in high-quality insulation become more apparent. Recyclable thermal insulation packs not only provide effective thermal performance but also contribute to long-term energy savings. This growing awareness of energy efficiency is likely to propel market growth, as stakeholders recognize the value of sustainable insulation solutions in mitigating energy costs. Consequently, the market is poised for expansion as energy efficiency becomes a priority.

Regulatory Support for Green Building Initiatives

Government regulations promoting green building practices are significantly influencing the Global Recyclable Thermal Insulation Pack Market Industry. Various countries are implementing stringent building codes that encourage the use of recyclable materials in construction. This regulatory support not only fosters innovation but also creates a favorable environment for manufacturers of recyclable thermal insulation packs. As a result, the market is expected to grow at a CAGR of 4.85% from 2025 to 2035, reaching an estimated 6.04 USD Billion by 2035. This growth indicates a robust alignment between regulatory frameworks and market dynamics, driving the adoption of sustainable insulation solutions.

Technological Advancements in Insulation Materials

Technological innovations are playing a pivotal role in shaping the Global Recyclable Thermal Insulation Pack Market Industry. Advances in material science have led to the development of high-performance recyclable insulation products that offer superior thermal efficiency. These innovations not only enhance the effectiveness of insulation but also contribute to reduced energy consumption in buildings. As energy efficiency becomes a critical focus for both consumers and regulators, the demand for technologically advanced recyclable thermal insulation packs is likely to increase. This trend underscores the importance of continuous research and development in maintaining competitiveness within the market.