Market Growth Projections

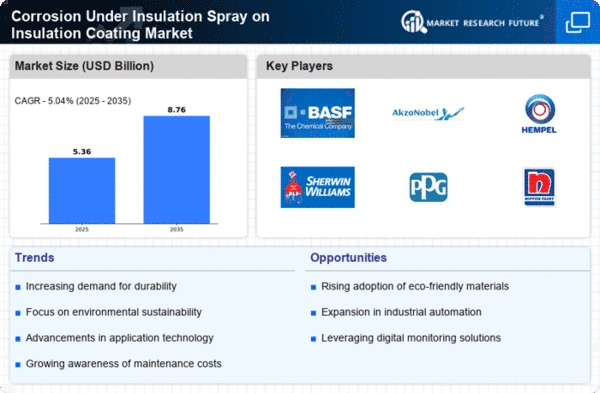

The Global Corrosion Under Insulation and Spray-on Insulation Coating Market Industry is projected to experience substantial growth, with estimates indicating a rise from 5.1 USD Billion in 2024 to 8.76 USD Billion by 2035. This growth trajectory suggests a compound annual growth rate of 5.04% from 2025 to 2035, reflecting increasing investments in corrosion protection technologies across various sectors. The market's expansion is likely to be driven by factors such as rising industrial infrastructure, regulatory compliance, and advancements in coating technologies. These projections highlight the importance of insulation coatings in maintaining asset integrity and operational efficiency.

Rising Industrial Infrastructure

The Global Corrosion Under Insulation and Spray-on Insulation Coating Market Industry is experiencing growth due to the increasing demand for industrial infrastructure. As industries expand, the need for effective insulation solutions becomes paramount to protect assets from corrosion. For instance, the oil and gas sector, which heavily relies on insulated pipelines, is projected to contribute significantly to the market. The market is expected to reach 5.1 USD Billion in 2024, reflecting the urgency for protective coatings that mitigate corrosion risks in harsh environments. This trend indicates a robust future for insulation coatings as industries prioritize asset longevity.

Expansion of Renewable Energy Sector

The Global Corrosion Under Insulation and Spray-on Insulation Coating Market Industry is benefiting from the expansion of the renewable energy sector. As countries shift towards sustainable energy sources, the need for reliable insulation solutions in wind, solar, and hydroelectric facilities is increasing. These installations often face unique environmental challenges that necessitate robust corrosion protection. The growth of renewable energy projects is expected to drive demand for specialized spray-on insulation coatings, contributing to the overall market growth. This trend aligns with global efforts to enhance energy efficiency and sustainability, further solidifying the market's future potential.

Growing Awareness of Maintenance Costs

The Global Corrosion Under Insulation and Spray-on Insulation Coating Market Industry is also being driven by a growing awareness of the long-term costs associated with corrosion damage. Industries are increasingly recognizing that investing in high-quality insulation coatings can significantly reduce maintenance and replacement expenses over time. For instance, studies indicate that effective insulation can lower energy costs and extend the lifespan of equipment. This realization is prompting companies to adopt proactive measures, thereby boosting the demand for spray-on insulation coatings. As a result, the market is poised for growth as organizations prioritize cost-effective solutions.

Regulatory Compliance and Safety Standards

The Global Corrosion Under Insulation and Spray-on Insulation Coating Market Industry is influenced by stringent regulatory frameworks aimed at ensuring safety and environmental protection. Governments worldwide are implementing regulations that mandate the use of corrosion-resistant materials in various sectors, including chemical processing and energy production. Compliance with these regulations not only enhances safety but also reduces maintenance costs associated with corrosion damage. As a result, the demand for advanced spray-on insulation coatings is likely to rise, contributing to the projected market growth to 8.76 USD Billion by 2035. This regulatory landscape fosters innovation in insulation technologies.

Technological Advancements in Coating Solutions

Innovations in coating technologies are driving the Global Corrosion Under Insulation and Spray-on Insulation Coating Market Industry. The development of advanced spray-on coatings that offer superior adhesion, flexibility, and resistance to extreme temperatures is enhancing the performance of insulation systems. For example, the introduction of nanotechnology in coatings has shown promise in improving durability and corrosion resistance. These advancements are likely to attract investments and increase market penetration, potentially leading to a compound annual growth rate of 5.04% from 2025 to 2035. The continuous evolution of coating solutions is essential for meeting the diverse needs of various industries.