Increased Focus on Automation

Automation remains a pivotal driver in the Punching Machine Market, as businesses strive to enhance operational efficiency and reduce labor costs. The trend towards Industry 4.0 has led to a significant increase in the adoption of automated punching machines, which are capable of performing complex tasks with minimal human intervention. In 2025, it is estimated that the market for automated machinery will reach a valuation of over 10 billion dollars, with punching machines constituting a substantial portion of this figure. This shift towards automation not only improves production rates but also ensures consistent quality in manufacturing processes. As companies continue to invest in smart manufacturing solutions, the Punching Machine Market is likely to see sustained growth, driven by the demand for machines that can seamlessly integrate into automated production lines.

Rising Demand in Manufacturing Sector

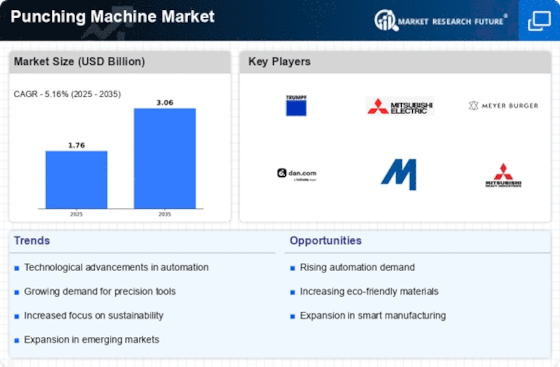

The Punching Machine Market is experiencing a notable surge in demand, primarily driven by the expansion of the manufacturing sector. As industries increasingly automate their processes, the need for efficient and precise punching machines has escalated. In 2025, the manufacturing sector is projected to grow at a compound annual growth rate of approximately 4.5%, which directly correlates with the rising adoption of punching machines. This growth is particularly evident in sectors such as automotive and electronics, where precision and speed are paramount. The Punching Machine Market is thus positioned to benefit from this trend, as manufacturers seek to enhance productivity and reduce operational costs. Furthermore, the integration of advanced technologies in punching machines, such as CNC and servo-driven systems, is likely to further stimulate market growth, as these innovations offer improved accuracy and efficiency.

Growing Emphasis on Quality and Precision

Quality and precision are paramount in the Punching Machine Market, as manufacturers increasingly prioritize these attributes to remain competitive. The demand for high-quality punched components is rising, particularly in sectors such as aerospace and medical devices, where precision is non-negotiable. In 2025, the market for precision engineering is projected to expand significantly, with punching machines playing a vital role in meeting these stringent requirements. Manufacturers are investing in high-precision punching machines that offer enhanced accuracy and repeatability, thereby ensuring that products meet the highest standards. This focus on quality not only enhances customer satisfaction but also reduces waste and rework, contributing to overall efficiency. Consequently, the Punching Machine Market is likely to thrive as companies seek to adopt machines that align with their quality assurance goals.

Emerging Markets and Infrastructure Development

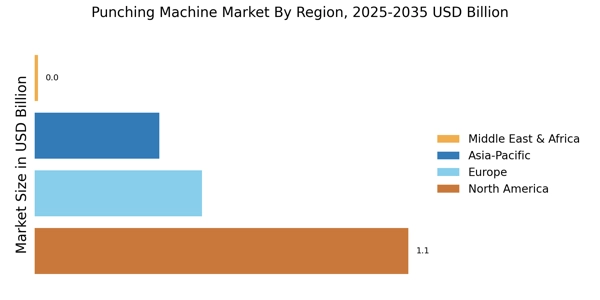

The Punching Machine Market is poised for growth due to the rapid development of infrastructure in emerging markets. Countries in Asia and Africa are witnessing significant investments in construction and manufacturing, leading to an increased demand for punching machines. In 2025, it is projected that the construction sector in these regions will grow by approximately 6%, creating a favorable environment for the punching machine market. As new factories and facilities are established, the need for efficient metalworking and fabrication processes becomes critical. This trend is further supported by government initiatives aimed at boosting industrialization, which in turn drives the demand for advanced punching machines. Consequently, the Punching Machine Market stands to benefit from these developments, as manufacturers seek to equip new facilities with state-of-the-art machinery.

Technological Innovations and Product Development

Technological advancements play a crucial role in shaping the Punching Machine Market. Continuous innovations in machine design and functionality are enhancing the capabilities of punching machines, making them more efficient and versatile. In 2025, the market is expected to witness the introduction of machines equipped with advanced features such as real-time monitoring and predictive maintenance. These innovations not only improve operational efficiency but also reduce downtime, which is a critical factor for manufacturers. The integration of IoT technology into punching machines allows for better data collection and analysis, enabling manufacturers to optimize their production processes. As a result, the Punching Machine Market is likely to experience growth driven by the demand for technologically advanced machines that can adapt to the evolving needs of various industries.