Automotive Industry Growth

The automotive sector plays a pivotal role in driving the Polypropylene and High Impact Polystyrene Market. As manufacturers increasingly prioritize lightweight materials to enhance fuel efficiency and reduce emissions, polypropylene has emerged as a preferred choice for various automotive components. High impact polystyrene is also gaining traction due to its impact resistance and aesthetic appeal. Recent statistics suggest that the automotive industry is projected to grow at a rate of 3.8% annually, further bolstering the demand for these polymers. This growth is indicative of a broader trend towards innovation in automotive design, where the integration of advanced materials is essential for meeting regulatory standards and consumer preferences.

Growth in Consumer Electronics

The consumer electronics sector is emerging as a significant driver for the Polypropylene and High Impact Polystyrene Market. With the proliferation of electronic devices, there is a rising demand for materials that offer durability and aesthetic appeal. High impact polystyrene is particularly favored for its excellent surface finish and ease of processing, making it ideal for housings and components in various electronic products. Market analysis indicates that the consumer electronics segment is expected to grow at a rate of 5% annually, reflecting the increasing reliance on technology in everyday life. This trend presents opportunities for manufacturers to innovate and cater to the evolving needs of consumers.

Rising Demand in Packaging Sector

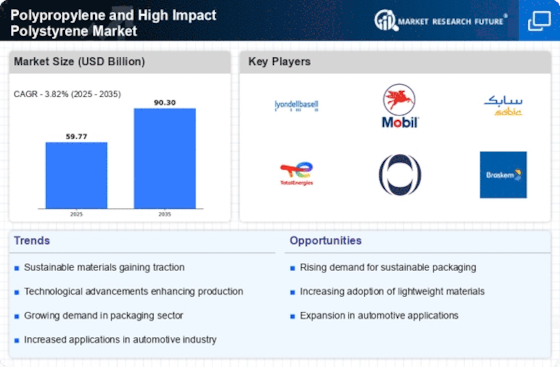

The Polypropylene and High Impact Polystyrene Market is experiencing a notable surge in demand, particularly within the packaging sector. This growth is largely attributed to the increasing need for lightweight, durable, and cost-effective materials. Polypropylene, known for its excellent chemical resistance and versatility, is widely utilized in food packaging, while high impact polystyrene is favored for its clarity and rigidity. According to recent data, the packaging segment accounts for a substantial portion of the overall market, with projections indicating a compound annual growth rate of approximately 4.5% over the next few years. This trend underscores the importance of these materials in meeting consumer expectations for convenience and sustainability.

Regulatory Support for Sustainable Materials

Regulatory frameworks promoting sustainability are increasingly impacting the Polypropylene and High Impact Polystyrene Market. Governments are implementing policies aimed at reducing plastic waste and encouraging the use of recyclable materials. This regulatory support is driving manufacturers to invest in sustainable practices and develop products that align with environmental standards. For instance, initiatives aimed at reducing single-use plastics are prompting a shift towards more sustainable alternatives, including recycled polypropylene. As these regulations become more stringent, they are likely to reshape market dynamics, compelling companies to adapt their strategies and innovate in order to remain competitive in a rapidly evolving landscape.

Technological Innovations in Polymer Production

Technological advancements in polymer production are significantly influencing the Polypropylene and High Impact Polystyrene Market. Innovations such as advanced catalytic processes and improved polymerization techniques are enhancing the efficiency and sustainability of production methods. These developments not only reduce energy consumption but also minimize waste, aligning with the increasing emphasis on environmental responsibility. Furthermore, the introduction of bio-based polypropylene is gaining attention, as it offers a renewable alternative to traditional fossil fuel-based materials. As these technologies evolve, they are likely to reshape the competitive landscape, providing manufacturers with opportunities to differentiate their products and meet the growing demand for sustainable solutions.