Technological Innovations

Technological advancements play a pivotal role in shaping the Polymerization Catalyst Market. Innovations in catalyst design and synthesis techniques are leading to more efficient and effective polymerization processes. For instance, the introduction of nanostructured catalysts has shown promise in enhancing reaction rates and selectivity. Furthermore, automation and digitalization in catalyst production are streamlining operations, reducing costs, and improving product quality. Market data indicates that the adoption of advanced technologies could potentially increase production efficiency by up to 30%, thereby attracting investments and fostering growth within the industry.

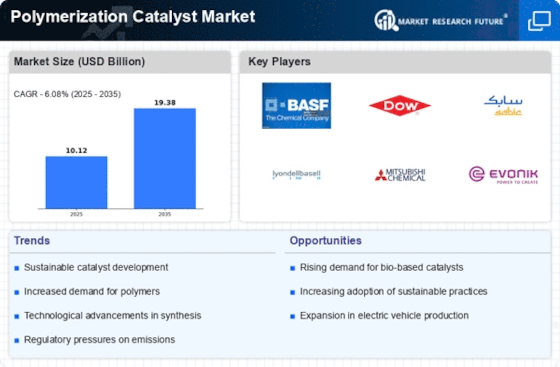

Sustainability Initiatives

The Polymerization Catalyst Market is increasingly influenced by sustainability initiatives. As industries strive to reduce their carbon footprint, the demand for eco-friendly catalysts is on the rise. This shift is driven by regulatory pressures and consumer preferences for sustainable products. Companies are investing in the development of catalysts that minimize waste and energy consumption during polymerization processes. The market for bio-based catalysts is projected to grow significantly, with estimates suggesting a compound annual growth rate of over 10% in the coming years. This trend not only aligns with environmental goals but also enhances the competitive edge of manufacturers who adopt sustainable practices.

Regulatory Compliance and Standards

Regulatory compliance is a significant driver in the Polymerization Catalyst Market. Governments worldwide are implementing stringent regulations regarding emissions and product safety, compelling manufacturers to adopt advanced catalysts that meet these standards. Compliance not only ensures market access but also enhances brand reputation. The increasing focus on health and safety regulations is pushing companies to innovate and develop catalysts that are less harmful to the environment and human health. As a result, the market for compliant catalysts is expected to expand, with projections indicating a growth rate of around 8% annually as industries adapt to these regulatory changes.

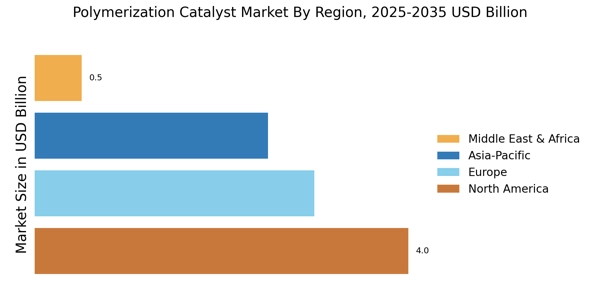

Emerging Markets and Economic Growth

Emerging markets are becoming increasingly vital to the Polymerization Catalyst Market. Rapid industrialization and urbanization in these regions are driving the demand for polymers in various applications. Countries in Asia and Latin America are witnessing significant economic growth, leading to increased investments in manufacturing and infrastructure. This growth is likely to boost the demand for polymerization catalysts, as industries seek to enhance production capabilities. Market analysis suggests that the Asia-Pacific region could account for over 40% of the total catalyst consumption by 2030, highlighting the potential for expansion in these emerging economies.

Rising Demand from End-User Industries

The Polymerization Catalyst Market is experiencing a surge in demand from various end-user sectors, including automotive, packaging, and construction. The automotive industry, in particular, is driving the need for high-performance polymers that require specialized catalysts for their production. As electric vehicles gain traction, the demand for lightweight and durable materials is expected to rise, further propelling the catalyst market. Recent statistics suggest that the automotive sector alone accounts for approximately 25% of the total catalyst consumption, indicating a robust growth trajectory. This trend underscores the importance of polymerization catalysts in meeting the evolving needs of diverse industries.