Regulatory Support

Regulatory frameworks promoting the use of biodegradable materials are likely to bolster the Polylactic Acid for 3D Printing Market. Governments worldwide are implementing policies aimed at reducing plastic waste and encouraging the adoption of sustainable materials. For instance, certain regions have introduced incentives for companies that utilize eco-friendly materials in their manufacturing processes. This regulatory support could potentially lead to a 10% increase in the adoption of PLA in 3D printing applications over the next few years. As regulations become more stringent regarding plastic usage, the Polylactic Acid for 3D Printing Market is expected to benefit from increased demand as businesses seek compliant and sustainable alternatives.

Diverse Application Range

The versatility of polylactic acid is a notable driver for the Polylactic Acid for 3D Printing Market. PLA is utilized across various sectors, including automotive, healthcare, and consumer goods, due to its favorable properties such as strength and ease of use. The healthcare sector, in particular, is witnessing a surge in demand for PLA-based 3D printed products, including prosthetics and surgical models. Market analysis suggests that the healthcare application segment could account for over 30% of the total PLA market share by 2026. This broad applicability not only enhances the attractiveness of PLA but also positions the Polylactic Acid for 3D Printing Market for sustained growth as new applications are continually explored.

Technological Innovations

Technological advancements in 3D printing techniques are significantly influencing the Polylactic Acid for 3D Printing Market. Innovations such as improved extrusion methods and enhanced printing speeds are making PLA a more viable option for various applications. The integration of advanced software and hardware solutions is enabling manufacturers to optimize their production processes, thereby increasing efficiency and reducing waste. Reports indicate that the adoption of these technologies could lead to a 15% reduction in production costs for companies utilizing PLA in their 3D printing operations. As these technologies continue to evolve, the Polylactic Acid for 3D Printing Market is expected to expand, attracting new players and fostering competition.

Sustainability Initiatives

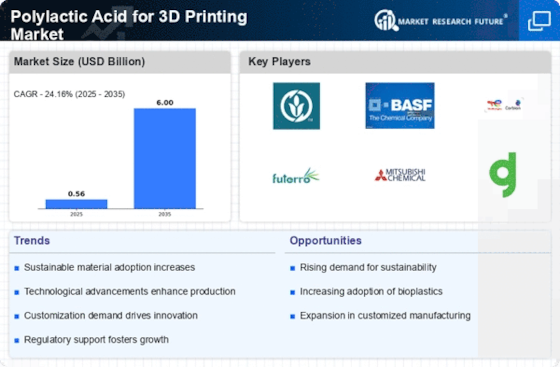

The increasing emphasis on sustainability appears to be a pivotal driver for the Polylactic Acid for 3D Printing Market. As environmental concerns gain traction, industries are seeking eco-friendly materials, and polylactic acid (PLA) emerges as a biodegradable alternative to traditional plastics. The market for PLA is projected to grow, with estimates suggesting a compound annual growth rate of around 20% over the next few years. This shift towards sustainable practices not only aligns with consumer preferences but also encourages manufacturers to adopt PLA in their 3D printing processes. Consequently, the Polylactic Acid for 3D Printing Market is likely to witness heightened demand as companies strive to reduce their carbon footprint and enhance their sustainability profiles.

Consumer Awareness and Demand

Growing consumer awareness regarding environmental issues is driving demand for sustainable products, including those made from polylactic acid. The Polylactic Acid for 3D Printing Market is experiencing a shift as consumers increasingly prefer products that are eco-friendly and biodegradable. Surveys indicate that over 60% of consumers are willing to pay a premium for products made from sustainable materials. This shift in consumer behavior is prompting manufacturers to incorporate PLA into their 3D printing processes to meet market expectations. As awareness continues to rise, the Polylactic Acid for 3D Printing Market is likely to see a corresponding increase in demand, further solidifying PLA's position in the market.