Technological Innovations

Technological advancements play a crucial role in shaping the Plasma Cutting Machine Market. Innovations such as automated plasma cutting systems and advanced control technologies enhance the precision and efficiency of cutting processes. The introduction of features like CNC (Computer Numerical Control) integration allows for greater automation, reducing human error and increasing productivity. Moreover, the development of high-definition plasma cutting technology has improved cut quality, making it suitable for a wider range of applications. As industries demand more sophisticated cutting solutions, manufacturers are compelled to invest in research and development to stay ahead. This focus on innovation is expected to drive the Plasma Cutting Machine Market forward, as companies seek to leverage cutting-edge technologies to meet evolving customer needs.

Focus on Energy Efficiency

The Plasma Cutting Machine Market is witnessing a growing emphasis on energy efficiency, driven by rising energy costs and environmental concerns. Manufacturers are increasingly seeking plasma cutting machines that consume less energy while maintaining high performance levels. Innovations in plasma technology have led to the development of energy-efficient machines that reduce power consumption without compromising cutting quality. This focus on sustainability aligns with global efforts to minimize carbon footprints and promote eco-friendly practices. Industry data suggests that energy-efficient plasma cutting machines can reduce operational costs by up to 30%, making them an attractive option for businesses. As companies prioritize sustainability in their operations, the Plasma Cutting Machine Market is likely to experience increased demand for energy-efficient solutions that contribute to both cost savings and environmental responsibility.

Growth in Construction Activities

The Plasma Cutting Machine Market is significantly influenced by the growth in construction activities across various regions. As urbanization accelerates, the demand for infrastructure development, including residential, commercial, and industrial projects, increases. This surge in construction activities necessitates efficient metal cutting solutions, which plasma cutting machines provide. According to industry reports, the construction sector is projected to grow at a CAGR of around 5% over the next few years, further fueling the demand for plasma cutting machines. These machines are essential for fabricating structural components, reinforcing bars, and other metal elements used in construction. Consequently, the Plasma Cutting Machine Market stands to gain from the ongoing expansion of construction projects, as companies seek reliable and efficient cutting technologies to support their operations.

Increasing Adoption of Automation

The trend towards automation in various industries significantly impacts the Plasma Cutting Machine Market. As companies strive to enhance productivity and reduce labor costs, the adoption of automated plasma cutting systems is on the rise. These systems not only improve cutting speed and accuracy but also minimize material waste, aligning with the growing emphasis on operational efficiency. Reports indicate that the automation market is expected to grow at a CAGR of approximately 7% in the coming years, suggesting a strong inclination towards automated solutions. This shift is likely to drive the demand for plasma cutting machines equipped with advanced automation features. As industries increasingly recognize the benefits of automation, the Plasma Cutting Machine Market is well-positioned to capitalize on this trend, offering solutions that meet the needs of modern manufacturing environments.

Rising Demand in Manufacturing Sector

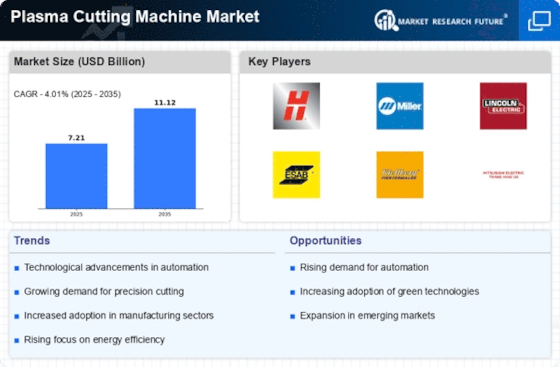

The Plasma Cutting Machine Market experiences a notable surge in demand, primarily driven by the expanding manufacturing sector. As industries increasingly adopt automation and advanced manufacturing techniques, the need for precise cutting solutions becomes paramount. In recent years, the manufacturing sector has shown a compound annual growth rate (CAGR) of approximately 4.5%, indicating a robust growth trajectory. This growth is likely to propel the demand for plasma cutting machines, which offer efficiency and accuracy in metal fabrication processes. Furthermore, the integration of Industry 4.0 technologies enhances the appeal of plasma cutting machines, as manufacturers seek to optimize production lines and reduce operational costs. Consequently, the Plasma Cutting Machine Market is poised to benefit from this upward trend in manufacturing, as companies invest in modern equipment to remain competitive.