Growth in Industrial Automation

The rise of industrial automation is a significant driver for the Non-Grain-Oriented Electrical Steel Market. As industries increasingly adopt automated systems, the demand for efficient electrical components, including motors and transformers, is on the rise. Non-grain-oriented electrical steel is essential for these applications due to its superior magnetic properties, which enhance the performance of electrical devices. The industrial automation market is projected to grow at a CAGR of approximately 8% by 2025, indicating a robust demand for high-quality electrical steel. This trend suggests that as automation technologies advance, the need for non-grain-oriented electrical steel will likely increase, further solidifying its role in modern manufacturing.

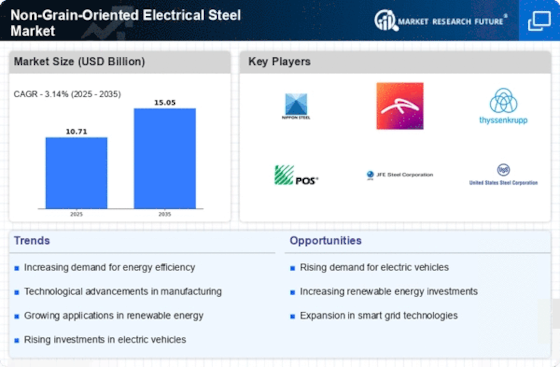

Rising Demand for Electric Vehicles

The increasing adoption of electric vehicles (EVs) is a pivotal driver for the Non-Grain-Oriented Electrical Steel Market. As automakers pivot towards electrification, the demand for high-performance electrical steel, which enhances motor efficiency, is expected to surge. In 2025, the EV market is projected to witness a compound annual growth rate (CAGR) of approximately 20%, thereby necessitating advanced materials like non-grain-oriented electrical steel. This steel type is crucial for manufacturing electric motors, which are integral to EV performance. Consequently, the growth in the EV sector is likely to bolster the demand for non-grain-oriented electrical steel, positioning it as a key material in the automotive industry.

Expansion of Renewable Energy Sources

The transition towards renewable energy sources is significantly influencing the Non-Grain-Oriented Electrical Steel Market. As countries strive to meet sustainability goals, investments in wind and solar energy are escalating. Wind turbines, which utilize non-grain-oriented electrical steel for their generators, are becoming increasingly prevalent. The market for wind energy is expected to grow at a CAGR of around 10% through 2025, thereby driving the demand for this specialized steel. The efficiency and performance of electrical components in renewable energy systems are paramount, and non-grain-oriented electrical steel plays a critical role in enhancing these attributes, thus supporting the industry's expansion.

Regulatory Support for Energy Efficiency

Regulatory frameworks aimed at enhancing energy efficiency are driving the Non-Grain-Oriented Electrical Steel Market. Governments worldwide are implementing stringent regulations to reduce energy consumption in electrical devices. These regulations often mandate the use of high-efficiency materials, such as non-grain-oriented electrical steel, in the production of transformers and motors. As a result, manufacturers are increasingly adopting this type of steel to comply with energy efficiency standards. The market for energy-efficient electrical equipment is expected to expand significantly, with non-grain-oriented electrical steel being a key component in meeting these regulatory requirements. This trend indicates a growing alignment between regulatory policies and market demand.

Technological Innovations in Manufacturing

Technological advancements in the manufacturing processes of non-grain-oriented electrical steel are propelling the Non-Grain-Oriented Electrical Steel Market forward. Innovations such as advanced coating techniques and improved alloy compositions are enhancing the magnetic properties of electrical steel, leading to better energy efficiency. These improvements are crucial as industries seek to reduce energy losses in electrical applications. The market is witnessing a shift towards higher-grade electrical steels, which are essential for applications requiring superior performance. As manufacturers adopt these technologies, the overall quality and efficiency of non-grain-oriented electrical steel are expected to improve, thereby increasing its market appeal.