Top Industry Leaders in the Multi Tasking Machine Tools Market

*Disclaimer: List of key companies in no particular order

Top listed global companies in the industry are:

- Yamazaki Mazak Corporation (Japan),

- Nakamura-Tome CO., LTD (Japan),

- Tongtai Machine & Tool Co., Ltd (China),

- Okuma Corporation (Japan),

- Tsugami Corporation (Japan),

- Trevisan Machine Tool (US),

- Doosan Corporation (South Korea),

- Accuway Machinery Corporation (China),

- Breton S.p.A. (Italy),

- DMG Mori (Japan),

- Hwacheon Machinery Co. Ltd (South Korea). among others

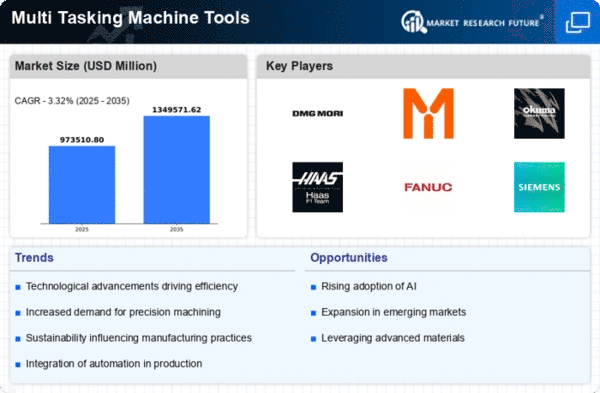

Multi-Tasking the Competition: Landscape of the Multi-Tasking Machine Tools Market

The multi-tasking machine tools market is a high-performance arena where established players compete with nimble innovators. Understanding the strategies driving this multi-faceted competition, the factors governing market share, and emerging trends is crucial for navigating this dynamic landscape.

Key Players and their Strategies:

- Global Titans: Giants like DMG Mori and Mazak leverage their extensive product portfolios, global reach, and brand recognition to command a significant market share. DMG Mori offers diverse multi-tasking machines (MTMs) across industries, while Mazak excels in integrating advanced technologies like automation and AI into its MTMs.

- Regional Champions: Companies like Yamazaki and Nakamura-Tome dominate specific geographies by tailoring solutions to regional regulations and industry needs. Yamazaki caters to Asia's manufacturing boom with cost-effective MTMs, while Nakamura-Tome excels in high-precision MTMs for Europe's aerospace and medical sectors.

- Technological Trailblazers: Startups like Huron and Five Axis Machining disrupt the market with cutting-edge approaches. Huron focuses on user-friendly, compact MTMs for small and medium-sized businesses, while Five Axis Machining pushes the boundaries with additive manufacturing integration into MTMs.

Factors for Market Share Analysis:

- Product Breadth and Depth: Offering a variety of MTMs for diverse applications (milling, turning, grinding) and workpiece sizes caters to varied customer needs and expands market reach.

- Technological Innovation: Integrating advanced features like multi-axis capabilities, automated tool changers, and digital controls enhances process efficiency, precision, and production flexibility. Mazak's AI-powered MTMs exemplify this.

- Cost-Effectiveness and ROI: Balancing advanced features with affordability is crucial, especially in budget-conscious segments. Yamazaki's cost-effective MTMs have secured a strong foothold in emerging markets.

- After-Sales Service and Support: Offering comprehensive after-sales support, including installation, training, and readily available spare parts, fosters customer loyalty and market penetration. DMG Mori excels in this area with its extensive service network.

Emerging Trends and Company Strategies:

- Smart MTMs: Integrating sensors, communication modules, and AI into MTMs enables real-time process monitoring, predictive maintenance, and data-driven optimization. Huron's cloud-connected MTMs exemplify this trend.

- Focus on Sustainability: Developing MTMs with energy-efficient components, minimal waste generation, and recyclable materials is gaining traction. Five Axis Machining's additive manufacturing integration contributes to this goal.

- Modular and Reconfigurable Systems: Offering modular MTMs with easy configuration changes fosters flexibility and adapts to evolving production needs. DMG Mori's modular machine concepts exemplify this.

- Focus on Specific Industries: Targeting high-growth segments like aerospace, medical, and electronics with specialized MTMs tailored to their precision and quality requirements is a growing trend. Nakamura-Tome's high-precision MTMs for the aerospace industry illustrate this approach.

Overall Competitive Scenario:

The multi-tasking machine tools market presents a dynamic landscape where global players clash with regional specialists and technology-driven startups. Success hinges on offering diverse and technologically advanced MTMs, balancing affordability with innovation, prioritizing service and support, and adapting to emerging trends like smart technologies, sustainability, and modularity. Companies demonstrating agility, industry-specific solutions, and a commitment to responsible manufacturing practices hold a strong hand in navigating this multi-tasking competition.

Latest Company Updates:

September 2023

Okuma, a Japanese machine tool manufacturer, will introduce the OSP-P500, a new CNC system, on stand B36 in hall 15. The in-house produced smart machine control combines energy efficiency, user-friendliness, safety features to ward off cyberattacks, and extremely productive and accurate machining.

The new machine control will initially be installed in Okuma's MU-V series 5-axis machining centers and the Multus series of multitasking turn-milling machines. According to NCMT, Okuma's sales representative for the UK and Ireland, cycle times can be shortened by up to 15% with this most recent CNC system, which has twice the processing power of traditional machine controls. When used in high-speed machining applications, it works especially well to produce extremely smooth surface finishes.

An on-machine Digital Twin installed in the control allows for high-precision simulation of machining operations, cutting setup times and increasing production rate. Production can begin right away by running these simulations on the machine itself.

September 2023

A new software suite called HxGN Production Machining was released by Hexagon's Manufacturing Intelligence division. It is intended to help machine shops achieve operational excellence in the production of discrete parts, tools, and components using machine tools at any scale, from large-scale production to one-off prototypes, and across a range of industries, including aerospace and medical.

A suite of capabilities, including shop-floor production intelligence, process simulation, G-code verification and optimization, CAM (computer-aided manufacturing) for CNC (computer numerical control) machine-tool programming, automation and collaboration, and CAD (computer-aided design) for manufacturing and design review, are available through Hexagon's digital reality platform, Nexus.