Increasing Demand for Metal Products

The Mining Metal Filtration Market is experiencing a surge in demand for metal products, driven by various sectors such as construction, automotive, and electronics. As industries expand, the need for high-quality metals increases, necessitating efficient filtration processes to ensure purity and compliance with stringent regulations. In 2025, the demand for metals is projected to grow at a compound annual growth rate of approximately 4.5%, which directly influences the filtration market. This trend indicates that companies involved in metal extraction and processing must invest in advanced filtration technologies to meet the rising quality standards and production volumes. Consequently, the Mining Metal Filtration Market is poised for growth as it adapts to these evolving demands.

Focus on Sustainable Mining Practices

The Mining Metal Filtration Market is increasingly influenced by the focus on sustainable mining practices. Companies are recognizing the importance of reducing their ecological footprint and are implementing filtration solutions that promote sustainability. This includes the use of recycled water in filtration processes and the reduction of waste generated during metal extraction. As sustainability becomes a core component of corporate strategies, the demand for innovative filtration technologies is likely to rise. In 2025, it is estimated that investments in sustainable mining technologies will reach significant levels, further driving the growth of the Mining Metal Filtration Market as firms seek to balance profitability with environmental responsibility.

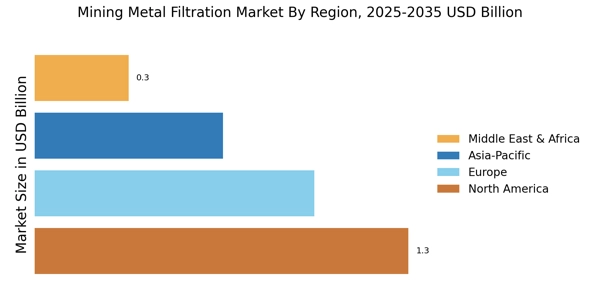

Rising Investment in Mining Infrastructure

The Mining Metal Filtration Market is benefiting from rising investments in mining infrastructure across various regions. Governments and private investors are channeling funds into the development of new mining projects and the expansion of existing operations. This influx of capital is expected to enhance the demand for efficient filtration systems that can support increased production capacities. In 2025, the mining sector is projected to see a substantial increase in capital expenditures, which will likely include investments in advanced filtration technologies. This trend indicates a promising outlook for the Mining Metal Filtration Market as it aligns with the broader growth of the mining sector.

Regulatory Compliance and Environmental Standards

The Mining Metal Filtration Market is significantly impacted by the increasing regulatory compliance requirements aimed at minimizing environmental impact. Governments and regulatory bodies are enforcing stricter guidelines regarding waste management and emissions, compelling mining companies to adopt advanced filtration systems. These systems not only enhance the quality of extracted metals but also reduce the environmental footprint of mining operations. In 2025, it is anticipated that compliance costs will rise, pushing companies to invest in efficient filtration technologies. This trend suggests that the Mining Metal Filtration Market will continue to grow as firms seek to align with environmental standards while maintaining operational efficiency.

Technological Innovations in Filtration Processes

The Mining Metal Filtration Market is witnessing rapid technological innovations that enhance filtration efficiency and effectiveness. Advancements in materials science and engineering have led to the development of new filtration media and systems that can operate under extreme conditions. For instance, the introduction of nanotechnology in filtration processes has shown potential in improving the separation of fine particles from metal ores. As these technologies become more accessible, mining companies are likely to adopt them to optimize their operations. The market for filtration technologies is expected to expand, with a projected growth rate of around 5% annually, indicating a robust future for the Mining Metal Filtration Market.