Expansion in the Construction Industry

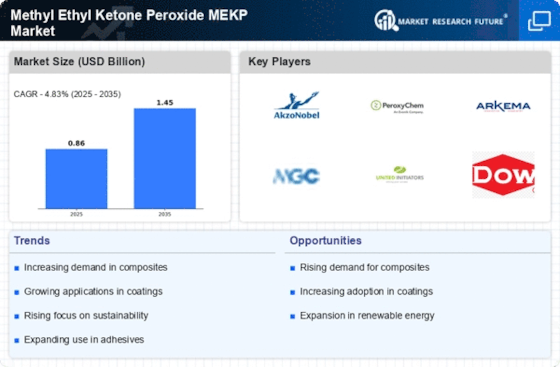

The Methyl Ethyl Ketone Peroxide MEKP Market is poised for growth, particularly due to the expansion of the construction industry. MEKP is extensively used in the production of composite materials, which are increasingly favored for their strength and lightweight properties in construction applications. The Methyl Ethyl Ketone Peroxide MEKP has shown a steady growth rate, with projections indicating a compound annual growth rate of around 5% through 2025. This growth is likely to enhance the demand for MEKP as builders and manufacturers seek materials that offer durability and efficiency. Furthermore, the trend towards prefabricated construction methods, which often utilize MEKP-based composites, is expected to further bolster the Methyl Ethyl Ketone Peroxide MEKP Market.

Growing Focus on Renewable Energy Sources

The Methyl Ethyl Ketone Peroxide MEKP Market is also benefiting from the growing focus on renewable energy sources. MEKP is utilized in the production of composite materials for wind turbine blades and other renewable energy applications. As countries strive to transition towards sustainable energy solutions, the demand for wind energy is expected to rise significantly. Reports indicate that the wind energy sector is projected to grow by over 10% annually through 2025, which will likely increase the consumption of MEKP in manufacturing processes. This shift towards renewable energy not only supports environmental goals but also enhances the market potential for MEKP, positioning the Methyl Ethyl Ketone Peroxide MEKP Market favorably in the coming years.

Rising Demand for High-Performance Coatings

The Methyl Ethyl Ketone Peroxide MEKP Market is witnessing a rising demand for high-performance coatings, which utilize MEKP as a key curing agent. These coatings are essential in various applications, including industrial, automotive, and marine sectors, where durability and resistance to environmental factors are paramount. The Methyl Ethyl Ketone Peroxide MEKP is projected to grow at a rate of approximately 4% annually, with high-performance coatings expected to capture a significant share of this growth. This trend is driven by the increasing need for protective coatings that can withstand harsh conditions, thereby enhancing the demand for MEKP. As industries prioritize quality and longevity in their products, the Methyl Ethyl Ketone Peroxide MEKP Market is likely to see sustained growth.

Increasing Applications in the Automotive Sector

The Methyl Ethyl Ketone Peroxide MEKP Market is experiencing a notable surge in demand due to its increasing applications in the automotive sector. MEKP is widely utilized as a curing agent in the production of fiberglass reinforced plastics, which are essential for manufacturing lightweight and durable automotive components. As the automotive industry continues to evolve towards more efficient and sustainable materials, the reliance on MEKP is likely to grow. In 2023, the automotive sector accounted for approximately 30% of the total MEKP consumption, indicating a robust market presence. This trend is expected to persist, driven by the ongoing innovations in vehicle design and the push for enhanced fuel efficiency, thereby propelling the Methyl Ethyl Ketone Peroxide MEKP Market further.

Technological Advancements in Manufacturing Processes

Technological advancements in manufacturing processes are significantly influencing the Methyl Ethyl Ketone Peroxide MEKP Market. Innovations in production techniques, such as improved synthesis methods and enhanced quality control measures, are leading to higher purity levels and better performance of MEKP. These advancements not only increase the efficiency of MEKP production but also expand its applicability across various sectors, including aerospace and marine industries. In 2023, the introduction of new manufacturing technologies has reportedly increased the production capacity of MEKP by approximately 15%, indicating a positive trend for the market. As manufacturers continue to adopt these technologies, the Methyl Ethyl Ketone Peroxide MEKP Market is likely to benefit from increased supply and reduced costs.