Technological Advancements

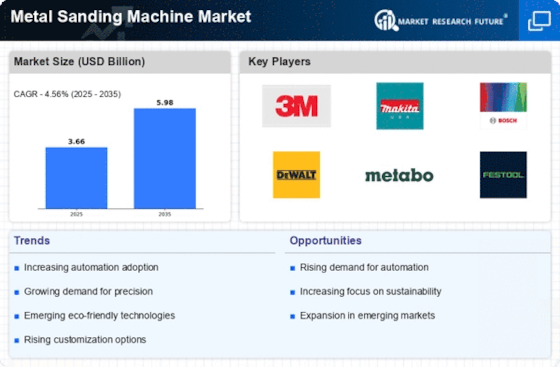

The Metal Sanding Machine Market is experiencing a surge in technological advancements that enhance machine efficiency and precision. Innovations such as computer numerical control (CNC) technology and advanced sanding materials are becoming increasingly prevalent. These advancements allow for more intricate designs and improved surface finishes, which are essential in industries such as automotive and aerospace. According to recent data, the adoption of CNC machines in the sanding process has increased productivity by up to 30%. This trend indicates a shift towards more automated solutions, which not only reduce labor costs but also minimize human error, thereby improving overall product quality. As manufacturers continue to invest in these technologies, the Metal Sanding Machine Market is likely to witness significant growth, driven by the demand for high-quality finishes and efficient production processes.

Focus on Quality and Surface Finish

In the Metal Sanding Machine Market, there is an increasing emphasis on quality and surface finish among manufacturers. As industries strive for excellence, the need for superior surface treatment has become paramount. High-quality finishes not only enhance the aesthetic appeal of products but also improve their durability and performance. This trend is particularly evident in sectors such as electronics and luxury goods, where surface quality can significantly impact consumer perception. Recent studies indicate that products with superior surface finishes can command a price premium of up to 20%. Consequently, manufacturers are investing in advanced sanding technologies to meet these quality demands, thereby propelling the Metal Sanding Machine Market. The focus on quality is likely to continue shaping market dynamics, as companies seek to differentiate themselves through superior product offerings.

Rising Demand from End-User Industries

The Metal Sanding Machine Market is significantly influenced by the rising demand from various end-user industries, including automotive, aerospace, and metal fabrication. These sectors require high-precision sanding solutions to meet stringent quality standards. For instance, the automotive industry is projected to grow at a compound annual growth rate (CAGR) of 4.5% over the next five years, which directly correlates with the increased need for metal sanding machines. Additionally, the aerospace sector's focus on lightweight materials and complex geometries necessitates advanced sanding technologies. This growing demand is prompting manufacturers to innovate and expand their product offerings, thereby driving the Metal Sanding Machine Market forward. The interplay between industry growth and technological advancements suggests a robust future for the market.

Growing Emphasis on Worker Safety and Ergonomics

The Metal Sanding Machine Market is increasingly influenced by a growing emphasis on worker safety and ergonomics. As awareness of workplace safety rises, manufacturers are prioritizing the development of sanding machines that minimize health risks associated with dust and noise exposure. Innovations such as dust extraction systems and noise-reducing technologies are becoming standard features in modern sanding machines. This shift not only protects workers but also enhances productivity by creating a safer working environment. According to industry reports, companies that invest in ergonomic machinery experience a 15% increase in employee satisfaction and retention. As safety regulations become more stringent, the Metal Sanding Machine Market is likely to evolve, with manufacturers focusing on creating safer, more ergonomic solutions.

Increased Investment in Manufacturing Infrastructure

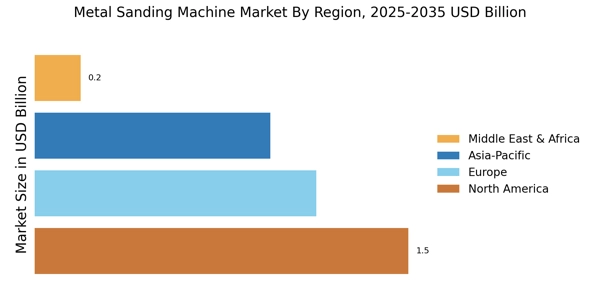

The Metal Sanding Machine Market is benefiting from increased investment in manufacturing infrastructure across various regions. Governments and private entities are recognizing the importance of modernizing manufacturing capabilities to enhance competitiveness. This investment is often directed towards upgrading existing facilities and acquiring advanced machinery, including metal sanding machines. For instance, recent government initiatives aimed at boosting manufacturing output have led to a rise in funding for equipment upgrades. As a result, manufacturers are more inclined to adopt state-of-the-art sanding technologies that improve efficiency and reduce production costs. This trend suggests a positive outlook for the Metal Sanding Machine Market, as enhanced manufacturing infrastructure is likely to drive demand for advanced sanding solutions.