Focus on Cost Reduction and Efficiency

In the Metal Fabrication Equipment Market, there is a growing emphasis on cost reduction and operational efficiency. Companies are increasingly seeking equipment that not only meets their production needs but also minimizes operational costs. This trend is driven by the need to maintain competitive pricing in a challenging market environment. Equipment that offers energy efficiency and lower maintenance costs is particularly attractive. As a result, manufacturers are investing in technologies that enhance productivity while reducing overall expenses, which is likely to propel the Metal Fabrication Equipment Market forward.

Rising Demand from End-User Industries

The Metal Fabrication Equipment Market is significantly influenced by the rising demand from various end-user sectors, including automotive, aerospace, and construction. These industries require high-quality metal components for their products, leading to an increased need for advanced fabrication equipment. For instance, the automotive sector is expected to grow at a compound annual growth rate of 4.5%, which will likely boost the demand for metal fabrication technologies. As these industries expand, the Metal Fabrication Equipment Market is poised to benefit from the heightened need for efficient and reliable fabrication solutions.

Emergence of Smart Manufacturing Practices

The Metal Fabrication Equipment Market is witnessing the emergence of smart manufacturing practices, which integrate IoT and data analytics into production processes. This shift towards smart factories allows for real-time monitoring and optimization of manufacturing operations. As companies adopt these technologies, they can enhance production efficiency and reduce downtime. The integration of smart technologies is expected to increase the overall market size of the Metal Fabrication Equipment Market, as manufacturers seek to leverage data-driven insights for improved decision-making and operational performance.

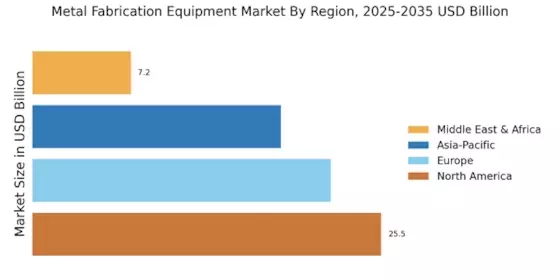

Increased Investment in Infrastructure Development

The Metal Fabrication Equipment Market is benefiting from increased investments in infrastructure development across various regions. Governments and private entities are allocating substantial funds for the construction of roads, bridges, and buildings, which in turn drives the demand for metal fabrication equipment. For example, infrastructure projects are projected to grow by 5% annually, creating a robust market for metal components. This trend indicates a sustained demand for advanced fabrication technologies, positioning the Metal Fabrication Equipment Market for continued growth as infrastructure projects expand.

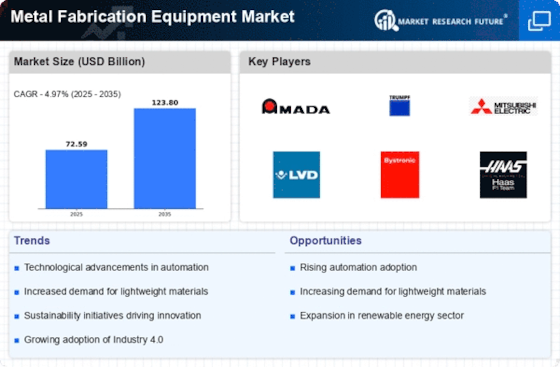

Technological Advancements in Metal Fabrication Equipment

The Metal Fabrication Equipment Market is experiencing a surge in technological advancements, particularly in automation and precision engineering. Innovations such as laser cutting, CNC machining, and 3D printing are revolutionizing the way metal components are produced. These technologies enhance efficiency, reduce waste, and improve product quality. According to recent data, the adoption of advanced manufacturing technologies is projected to increase productivity by up to 30% in the next few years. As manufacturers seek to remain competitive, investments in state-of-the-art equipment are likely to rise, driving growth in the Metal Fabrication Equipment Market.