Focus on Energy Efficiency

Energy efficiency is becoming a critical focus within the Industrial Gases Metal Fabrication Market. As manufacturers strive to reduce operational costs and minimize environmental impact, the adoption of energy-efficient technologies is on the rise. Industrial gases play a pivotal role in enhancing energy efficiency during metal fabrication processes. For instance, the use of oxygen-enriched combustion can lead to higher temperatures and improved fuel efficiency. This trend is likely to drive the demand for industrial gases, as companies seek to optimize their processes. Furthermore, regulatory pressures aimed at reducing carbon emissions may compel manufacturers to adopt cleaner technologies, thereby increasing the reliance on industrial gases. The emphasis on energy efficiency is expected to shape the future landscape of the Industrial Gases Metal Fabrication Market.

Growth of Additive Manufacturing

The emergence of additive manufacturing, commonly known as 3D printing, is significantly influencing the Industrial Gases Metal Fabrication Market. This innovative technology allows for the creation of complex metal parts with reduced waste and enhanced design flexibility. As additive manufacturing gains traction across various sectors, the demand for specific industrial gases, such as nitrogen and argon, is likely to increase. These gases are essential for creating inert atmospheres during the printing process, ensuring high-quality outputs. The additive manufacturing market is projected to grow at a rate of around 25% annually, which could substantially impact the industrial gases sector. Consequently, the Industrial Gases Metal Fabrication Market is poised to benefit from this technological advancement, as companies adapt to the evolving landscape of manufacturing.

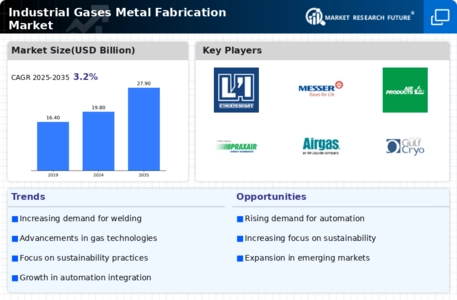

Rising Demand for Metal Fabrication

The Industrial Gases Metal Fabrication Market is experiencing a notable increase in demand due to the expanding metal fabrication sector. Industries such as automotive, aerospace, and construction are driving this growth, as they require high-quality metal components. The demand for fabricated metal products is projected to grow at a compound annual growth rate of approximately 4.5% over the next few years. This growth is likely to be fueled by the need for lightweight materials and advanced manufacturing techniques. As a result, the consumption of industrial gases, such as oxygen and argon, is expected to rise significantly, supporting the overall market expansion. The increasing complexity of metal fabrication processes necessitates the use of specialized gases, further enhancing the relevance of the Industrial Gases Metal Fabrication Market.

Increasing Automation in Manufacturing

Automation is transforming the landscape of the Industrial Gases Metal Fabrication Market. The integration of advanced robotics and automated systems in manufacturing processes is enhancing productivity and precision. As companies seek to streamline operations and reduce labor costs, the demand for industrial gases is likely to rise. Automated welding and cutting processes require specific gases to achieve optimal results, thereby driving consumption. The trend towards automation is expected to continue, with investments in smart manufacturing technologies projected to reach billions in the coming years. This shift not only improves efficiency but also necessitates the use of specialized industrial gases, further solidifying their role in the Industrial Gases Metal Fabrication Market.

Regulatory Compliance and Safety Standards

Regulatory compliance and safety standards are increasingly influencing the Industrial Gases Metal Fabrication Market. Governments and industry bodies are implementing stringent regulations to ensure safe handling and usage of industrial gases. Compliance with these regulations is essential for manufacturers to avoid penalties and ensure operational continuity. As safety standards evolve, the demand for high-purity industrial gases is likely to increase, as they are crucial for maintaining quality and safety in metal fabrication processes. Additionally, companies are investing in training and safety equipment to adhere to these regulations, which may further drive the consumption of industrial gases. The focus on regulatory compliance is expected to shape the operational strategies within the Industrial Gases Metal Fabrication Market.