Expansion of the Construction Industry

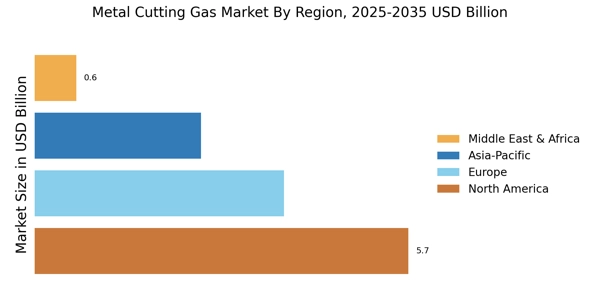

The Metal Cutting Gas Market is benefiting from the expansion of the construction industry, which is experiencing robust growth. As infrastructure projects and residential developments increase, the demand for metal cutting services rises correspondingly. This trend is particularly evident in regions where urbanization is accelerating, leading to a heightened need for metal components in construction. Market analysis indicates that the construction sector could account for a significant portion of the Metal Cutting Gas Market, with projections estimating a growth rate of around 8% over the next few years. This expansion presents opportunities for gas suppliers to cater to the increasing needs of construction firms.

Environmental Regulations and Compliance

The Metal Cutting Gas Market is influenced by stringent environmental regulations aimed at reducing emissions and promoting sustainable practices. Governments are implementing policies that encourage the use of cleaner cutting gases, which has led to a shift in market dynamics. For instance, the adoption of gases with lower environmental impact is becoming a priority for many manufacturers. This shift not only aligns with regulatory requirements but also enhances corporate sustainability initiatives. As a result, the Metal Cutting Gas Market is likely to see a rise in demand for eco-friendly gas solutions, potentially increasing market share for companies that prioritize compliance and sustainability.

Growing Demand from the Manufacturing Sector

The Metal Cutting Gas Market is witnessing a notable increase in demand driven by the manufacturing sector. As industries such as automotive, aerospace, and construction expand, the need for efficient metal cutting solutions becomes paramount. The manufacturing sector's growth is projected to contribute significantly to the Metal Cutting Gas Market, with estimates suggesting a market size increase of around 10% annually. This growth is largely attributed to the rising production of metal components and the need for precision cutting in various applications. Consequently, manufacturers are increasingly investing in high-quality metal cutting gases to meet the evolving demands of their production processes.

Rising Adoption of Laser Cutting Technologies

The Metal Cutting Gas Market is witnessing a rising adoption of laser cutting technologies, which are revolutionizing traditional cutting methods. Laser cutting offers precision and efficiency that are often unmatched by conventional techniques. As industries seek to enhance their production capabilities, the integration of laser cutting systems is becoming more prevalent. This trend is likely to drive demand for specific gases that optimize laser cutting processes, such as assist gases that improve cut quality. Market forecasts suggest that the segment of the Metal Cutting Gas Market associated with laser cutting could grow significantly, potentially reaching a market share increase of 15% in the coming years.

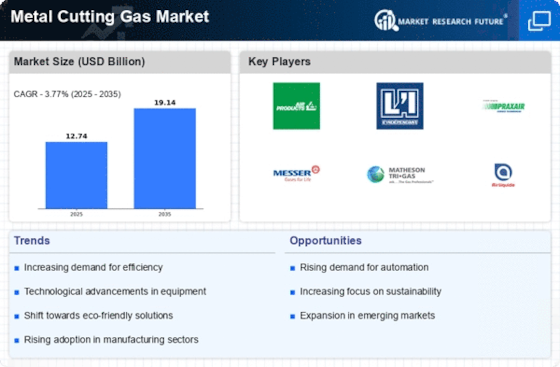

Technological Innovations in Metal Cutting Gas Market

The Metal Cutting Gas Market is experiencing a surge in technological innovations that enhance cutting efficiency and precision. Advanced gas mixtures and delivery systems are being developed, which optimize the cutting process. For instance, the introduction of high-purity gases has been shown to improve the quality of cuts and reduce waste. Furthermore, the integration of automation technologies in gas delivery systems is streamlining operations, thereby increasing productivity. According to recent data, the adoption of these technologies is projected to grow at a compound annual growth rate of approximately 5% over the next five years. This trend indicates a robust demand for innovative solutions within the Metal Cutting Gas Market, as manufacturers seek to improve their operational capabilities.