Market Analysis

In-depth Analysis of Manufacturing Analytics Market Industry Landscape

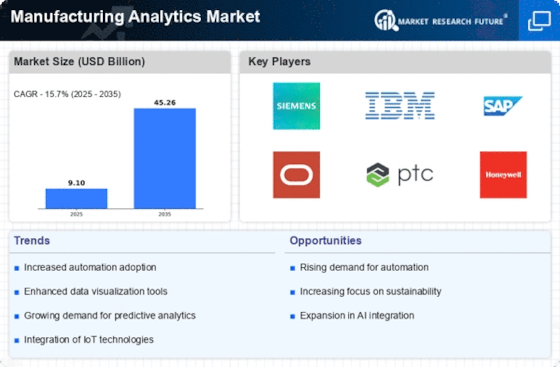

The Manufacturing Analytics market is currently experiencing a dynamic landscape shaped by various market forces. As industries worldwide continue to embrace digital transformation, the demand for manufacturing analytics solutions has witnessed significant growth. This surge can be attributed to the industry's recognition of the value that data-driven insights bring to the manufacturing process. Market dynamics are shaped by several key factors, including the increasing adoption of advanced technologies such as the Internet of Things (IoT) and Artificial Intelligence (AI) in manufacturing operations.

One of the driving forces behind the growth of the Manufacturing Analytics market is the pressing need for enhanced operational efficiency. Manufacturers are leveraging analytics to optimize their production processes, identify bottlenecks, and streamline operations. This efficiency-driven approach is not only cost-effective but also helps in maintaining high-quality standards. Additionally, the rising importance of predictive maintenance is influencing the market dynamics. Manufacturers are employing analytics to predict equipment failures before they occur, minimizing downtime and reducing maintenance costs.

Moreover, the market is witnessing a shift towards real-time analytics. With the increasing speed of business operations, manufacturers are recognizing the importance of real-time insights to make informed decisions promptly. Real-time analytics enables quick response to changing market conditions, demand fluctuations, and unforeseen disruptions, thereby improving overall agility. This shift towards real-time capabilities is steering the manufacturing analytics market towards more sophisticated and advanced solutions.

The role of data security and privacy concerns is another crucial aspect shaping the market dynamics of Manufacturing Analytics. As the volume of data generated by manufacturing processes increases, the need for robust security measures becomes paramount. Manufacturers are looking for analytics solutions that not only provide valuable insights but also ensure the integrity and confidentiality of sensitive data. This emphasis on data security is driving innovation in the manufacturing analytics market, with vendors developing advanced encryption and authentication mechanisms.

Furthermore, the emergence of cloud-based solutions is contributing to the evolving landscape of the Manufacturing Analytics market. Cloud platforms offer scalability, accessibility, and cost-effectiveness, making them an attractive option for manufacturers looking to deploy analytics solutions. The cloud-based approach allows manufacturers to overcome traditional infrastructure limitations, facilitating easier integration of analytics into existing systems. This trend is likely to continue as more manufacturers recognize the benefits of cloud-based analytics in terms of flexibility and scalability.

The global nature of modern manufacturing is also influencing market dynamics. Manufacturers operating on a global scale are seeking analytics solutions that provide visibility across multiple facilities and supply chain networks. This demand for comprehensive analytics platforms that can handle the complexity of global operations is driving vendors to develop solutions with robust cross-functional and cross-border capabilities.

Leave a Comment