Rising Demand in Oil and Gas Sector

The Instrumentation Valve Fitting Market is experiencing a notable surge in demand, particularly from the oil and gas sector. This industry relies heavily on precision instrumentation to ensure safety and efficiency in operations. As exploration and production activities expand, the need for reliable valve fittings becomes paramount. In 2025, the oil and gas sector is projected to account for a significant share of the market, driven by increasing investments in infrastructure and technology. The emphasis on safety regulations further propels the demand for high-quality instrumentation valve fittings, as companies seek to minimize risks associated with leaks and failures. Consequently, manufacturers are focusing on developing advanced valve fitting solutions that meet stringent industry standards, thereby enhancing their market presence.

Growth in Chemical Processing Industries

The Instrumentation Valve Fitting Market is poised for growth due to the expanding chemical processing industries. These industries require robust and reliable valve fittings to manage the flow of various chemicals safely. As production capacities increase, the demand for high-performance instrumentation valve fittings is likely to rise. In 2025, the chemical processing sector is expected to contribute significantly to market growth, driven by the need for automation and process optimization. Companies are increasingly investing in advanced instrumentation technologies to enhance operational efficiency and safety. This trend indicates a shift towards more sophisticated valve fitting solutions that can withstand harsh chemical environments, thereby creating opportunities for manufacturers to innovate and expand their product offerings.

Regulatory Compliance and Safety Standards

The Instrumentation Valve Fitting Market is significantly influenced by the stringent regulatory compliance and safety standards imposed across various sectors. Industries such as oil and gas, pharmaceuticals, and food processing are required to adhere to rigorous safety protocols to prevent accidents and ensure product quality. As regulations evolve, the demand for high-quality instrumentation valve fittings that meet these standards is expected to increase. In 2025, manufacturers are likely to focus on developing valve fittings that not only comply with existing regulations but also anticipate future requirements. This proactive approach may enhance their competitive edge in the market, as companies seek to mitigate risks associated with non-compliance and enhance their reputation for safety and reliability.

Emerging Markets and Infrastructure Development

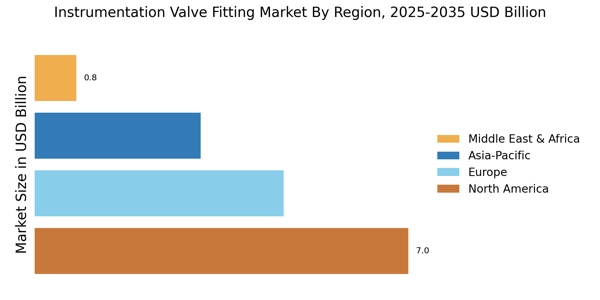

The Instrumentation Valve Fitting Market is benefiting from the growth of emerging markets and ongoing infrastructure development projects. As countries invest in upgrading their industrial capabilities, the demand for reliable instrumentation valve fittings is expected to rise. In 2025, regions experiencing rapid industrialization are likely to present lucrative opportunities for manufacturers. The expansion of sectors such as energy, water treatment, and manufacturing in these markets necessitates the deployment of advanced valve fitting solutions. This trend suggests that manufacturers may need to adapt their strategies to cater to the specific needs of these emerging markets, potentially leading to increased collaboration with local partners and tailored product offerings.

Increased Focus on Automation and Control Systems

The Instrumentation Valve Fitting Market is witnessing a transformation driven by the increased focus on automation and control systems across various sectors. Industries such as manufacturing, pharmaceuticals, and food processing are adopting automated solutions to enhance productivity and reduce operational costs. This shift necessitates the integration of advanced instrumentation valve fittings that can seamlessly connect with automated systems. In 2025, the market is likely to see a rise in demand for smart valve fittings equipped with sensors and IoT capabilities, enabling real-time monitoring and control. This trend not only improves efficiency but also enhances safety and compliance with regulatory standards, positioning manufacturers to capitalize on the growing need for innovative solutions in the instrumentation valve fitting market.