Expansion of End-User Industries

The expansion of end-user industries is a critical driver for the Industrial Coating Equipment Market. Sectors such as construction, electronics, and consumer goods are experiencing robust growth, leading to increased demand for coating solutions. For instance, the construction industry is projected to grow at a rate of 6% annually, driven by infrastructure development and urbanization. This growth necessitates high-performance coatings for various applications, including protective and decorative finishes. As end-user industries expand, they require advanced coating equipment to meet their specific needs, thereby propelling the growth of the Industrial Coating Equipment Market. Manufacturers are likely to respond by innovating and diversifying their product offerings to capture this expanding market.

Rising Demand for Durable Coatings

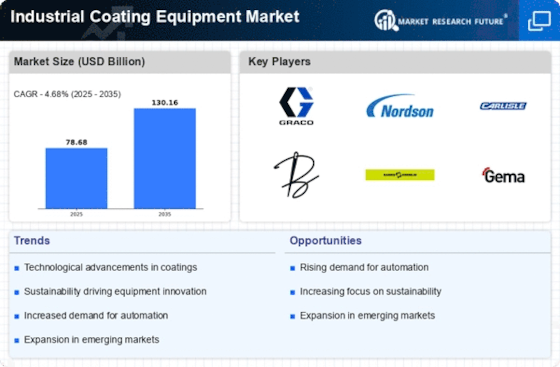

The Industrial Coating Equipment Market is experiencing a notable increase in demand for durable coatings, driven by the need for enhanced protection against corrosion and wear. Industries such as automotive, aerospace, and construction are increasingly adopting advanced coating solutions to extend the lifespan of their products. According to recent data, the demand for protective coatings is projected to grow at a compound annual growth rate of approximately 5.5% over the next few years. This trend indicates a shift towards high-performance coatings that can withstand harsh environmental conditions. As manufacturers seek to improve product longevity and reduce maintenance costs, the Industrial Coating Equipment Market is likely to benefit from this rising demand, prompting innovations in coating technologies and equipment.

Growth in Automotive and Aerospace Sectors

The Industrial Coating Equipment Market is significantly influenced by the growth in the automotive and aerospace sectors. These industries require high-quality coatings to ensure safety, aesthetics, and durability of their products. The automotive sector, in particular, is witnessing a shift towards electric vehicles, which necessitate advanced coating solutions for battery components and lightweight materials. Recent statistics indicate that the aerospace industry is expected to grow at a rate of 4.2% annually, further driving the need for specialized coating equipment. This growth presents opportunities for manufacturers of industrial coating equipment to develop innovative solutions tailored to the specific requirements of these sectors, thereby enhancing their market position.

Technological Innovations in Coating Processes

Technological innovations are reshaping the Industrial Coating Equipment Market, with advancements in automation and digitalization playing a pivotal role. The integration of smart technologies, such as IoT and AI, into coating processes is enhancing efficiency and precision. For instance, automated spray systems and robotic arms are increasingly utilized to achieve consistent coating applications, reducing waste and improving productivity. Furthermore, the introduction of eco-friendly coating materials is gaining traction, aligning with sustainability goals across various industries. As these technologies evolve, they are likely to drive the demand for advanced industrial coating equipment, enabling manufacturers to meet the growing expectations for quality and performance.

Regulatory Compliance and Environmental Standards

The Industrial Coating Equipment Market is also shaped by stringent regulatory compliance and environmental standards. Governments worldwide are implementing regulations aimed at reducing volatile organic compounds (VOCs) and promoting the use of environmentally friendly coatings. This regulatory landscape compels manufacturers to invest in advanced coating technologies that comply with these standards. As a result, there is a growing demand for equipment that can apply low-VOC and water-based coatings effectively. The shift towards sustainable practices not only addresses regulatory requirements but also aligns with consumer preferences for eco-friendly products, thereby creating a favorable environment for the Industrial Coating Equipment Market.