Market Trends

Key Emerging Trends in the In mold Labels Market

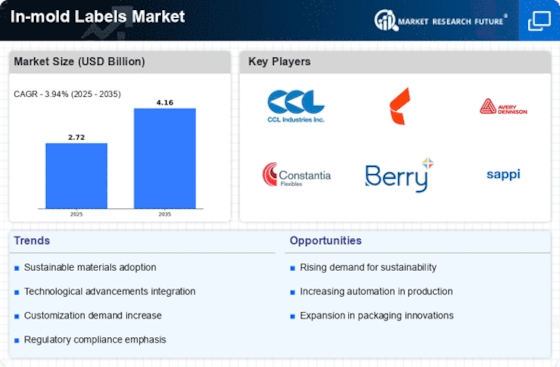

The in-mold labels market is experiencing significant trends driven by various factors influencing consumer preferences and industry dynamics. One notable trend is the increasing demand for visually appealing and high-quality packaging solutions. In-mold labels offer vibrant graphics, crisp images, and premium printing finishes that enhance product presentation and shelf appeal. As a result, there's a growing adoption of in-mold labels across various industries, including food and beverage, personal care, household products, and automotive, where brands seek to differentiate their products and attract consumer attention on crowded retail shelves.

Global in-mold labels market has been segmented based on technology, material, application, and region. Based on technology the market is segmented into extrusion blow-molding process, injection molding process, thermoforming, and others. Among these, injection molding is projected to dominate the in-mold labels market until 2023. The dominant position of this segment can be attributed to the provision of a 3-Dimensional effect to the labels, along with economical operations as compared to other technologies. Based on the material, the market is segmented into polypropylene, polyvinylchloride, ABS resins, and others.

Another prominent trend in the in-mold labels market is the shift towards sustainable packaging solutions. With growing concerns about environmental sustainability and plastic waste, there's a heightened focus on eco-friendly labeling options. In-mold labels, which are applied directly to packaging containers during the manufacturing process, eliminate the need for additional labeling materials such as adhesives or liners, reducing overall packaging waste. Additionally, in-mold labels can be made from recyclable materials such as polypropylene (PP) or polyethylene (PE), making them compatible with existing recycling streams and supporting circular economy initiatives.

Furthermore, the rise of digital printing technologies is driving innovation in the in-mold labels market. Digital printing offers advantages such as high-quality printing, variable data capabilities, and shorter lead times compared to traditional printing methods. This enables brands to create customized and personalized in-mold labels with intricate designs, vibrant colors, and unique features tailored to specific products or promotional campaigns. Digital printing also allows for on-demand printing, reducing inventory costs and enabling quick turnaround times for product launches and seasonal promotions.

Moreover, the growing popularity of convenience and on-the-go lifestyles is fueling demand for in-mold labels with added functionality and usability features. In-mold labels with integrated features such as resealable closures, peel-and-reseal options, and single-serve packaging formats cater to consumers' needs for convenience, portion control, and product freshness. These functional in-mold labels enhance consumer experience and satisfaction, driving brand loyalty and repeat purchases in competitive markets.

Additionally, regulatory compliance and safety considerations are shaping the in-mold labels market landscape. In industries such as food and beverage, pharmaceuticals, and cosmetics, in-mold labels must comply with stringent regulations related to product labeling, safety warnings, and information disclosure. Manufacturers and brands must ensure that in-mold labels meet regulatory requirements for food contact materials, chemical migration limits, and product safety standards to ensure consumer safety and regulatory compliance.

Furthermore, the COVID-19 pandemic has influenced certain trends in the in-mold labels market, particularly in terms of hygiene and safety considerations. With increased focus on hygiene practices and infection prevention, there's a growing demand for packaging materials that offer antimicrobial properties and enhanced barrier protection. In-mold labels with antimicrobial coatings, tamper-evident seals, and other safety features are witnessing greater adoption in industries such as healthcare, pharmaceuticals, and food service, where maintaining product safety and integrity is paramount.

Leave a Comment