Rising Environmental Concerns

The Hydrogen Tank Material Market is increasingly shaped by rising environmental concerns and the urgent need for sustainable energy solutions. As climate change becomes a pressing global issue, there is a growing emphasis on reducing carbon emissions and transitioning to cleaner energy sources. Hydrogen, recognized for its potential to decarbonize various sectors, is gaining traction as a sustainable alternative. This shift is prompting manufacturers in the Hydrogen Tank Material Market to explore eco-friendly materials and production processes. The focus on sustainability is driving innovation in the development of recyclable and biodegradable materials for hydrogen tanks, which could significantly reduce the environmental impact of hydrogen storage solutions. As consumers and industries alike prioritize sustainability, the demand for environmentally friendly hydrogen tank materials is expected to rise, influencing market dynamics.

Government Initiatives and Funding

The Hydrogen Tank Material Market is benefiting from various government initiatives aimed at promoting hydrogen as a clean energy source. Many governments are implementing policies and providing funding to support research and development in hydrogen technologies, including storage solutions. For example, several countries have established hydrogen roadmaps that outline strategies for increasing hydrogen production, distribution, and utilization. These initiatives often include financial incentives for companies investing in innovative materials for hydrogen tanks. As a result, the Hydrogen Tank Material Market is likely to see increased investment in advanced materials that enhance the safety and efficiency of hydrogen storage. This supportive regulatory environment is expected to foster collaboration between public and private sectors, leading to accelerated advancements in hydrogen tank technologies.

Expansion of Hydrogen Infrastructure

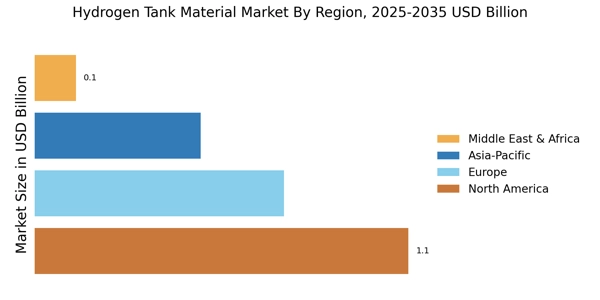

The Hydrogen Tank Material Market is poised for growth due to the ongoing expansion of hydrogen infrastructure worldwide. As countries invest in hydrogen production, distribution, and refueling stations, the need for reliable and efficient hydrogen storage solutions becomes paramount. This infrastructure development is essential for supporting the adoption of hydrogen as a mainstream energy source. Recent reports indicate that investments in hydrogen infrastructure are expected to reach billions of dollars in the next few years, creating a robust market for hydrogen storage solutions. Consequently, the Hydrogen Tank Material Market is likely to see increased demand for advanced materials that can meet the stringent requirements of hydrogen storage and transport. The expansion of infrastructure not only facilitates the growth of the hydrogen economy but also drives innovation in materials used for hydrogen tanks, ensuring their safety and efficiency.

Growing Demand for Hydrogen Fuel Cells

The Hydrogen Tank Material Market is significantly influenced by the increasing demand for hydrogen fuel cells across various applications, including transportation and stationary power generation. As industries seek to transition towards cleaner energy sources, hydrogen fuel cells are emerging as a viable alternative to traditional fossil fuels. According to recent estimates, the hydrogen fuel cell market is projected to grow at a compound annual growth rate of over 20% in the coming years. This growth is driving the need for efficient and reliable hydrogen storage solutions, thereby propelling the demand for advanced materials in the Hydrogen Tank Material Market. Manufacturers are focusing on developing tanks that can withstand high pressures and temperatures, ensuring the safe storage and transport of hydrogen, which is crucial for the widespread adoption of fuel cell technologies.

Technological Advancements in Hydrogen Storage

The Hydrogen Tank Material Market is experiencing a surge in technological advancements that enhance the efficiency and safety of hydrogen storage solutions. Innovations in materials science, such as the development of high-strength composites and advanced alloys, are enabling the production of lighter and more durable tanks. These advancements not only improve the performance of hydrogen tanks but also reduce costs associated with manufacturing and transportation. For instance, the introduction of carbon fiber reinforced polymers has shown potential in reducing the weight of tanks by up to 50%, thereby increasing their storage capacity. As the demand for hydrogen as a clean energy source continues to rise, the Hydrogen Tank Material Market is likely to benefit from these technological innovations, which could lead to a more competitive landscape and expanded applications in various sectors.