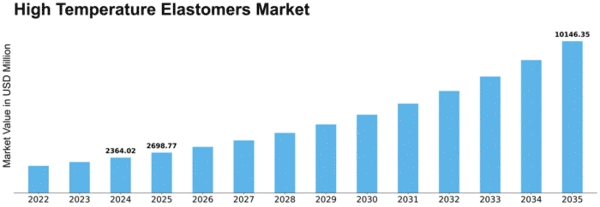

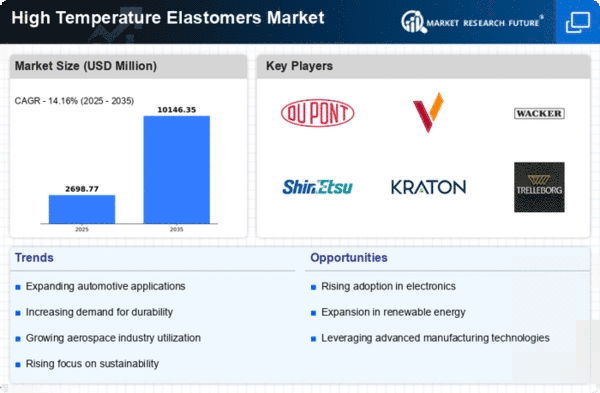

High Temperature Elastomers Size

High Temperature Elastomers Market Growth Projections and Opportunities

The High Temperature Elastomers market is influenced by several key factors that shape its dynamics and growth trajectory. The increasing need for materials capable of withstanding high temperatures, while still maintaining flexibility and strength, forms the principal driving factor in their high temperature elastomers demand across multiple sectors. Particularly, this demand surge is witnessed in industries such as automotive, aerospace and oil and gas where components are exposed to extreme temperatures during operations. In order for these industries to continue evolving and pushing performance boundaries, it becomes necessary to use high-temperature elastomers to increase the reliability and longevity of the crucial component parts.

Another significant factor impacting the High Temperature Elastomers market is the constant advancements in technology and materials science. The market sees development of new elastomers with better temperature resistance properties, improved mechanical characteristics or stronger chemical compatibility as researches keep on advancing formulation techniques coupled with manufacturing processes. As well as meeting the ever-increasing demand for higher performing materials; these technological breakthroughs also add up to overall industry competitiveness.

The High-Temperature Elastomers Market is expected to grow USD 23.4 billion at a CAGR of around 5.2% by 2030

The regulatory landscape also plays a pivotal role in shaping the High Temperature Elastomers market. Harsh regulations relating to safety and environmental standards applicable in different sectors necessitate adoption of materials that comply with them. In order to satisfy these statutory requirements, there is often need for use of high temperature elastomer which can withstand unfavorable conditions. Besides; the growing emphasis on sustainability together with an aim of reducing environmental impact has led to development of elastomers that are not only efficient but also eco-friendly.

Global economic factors including GDP growth, industrialization, infrastructure developments significantly affect the High Temperature Elastomers market. Expansion of economies consequently leads into more durable reliable material demands thus expanding industries that rely on high temperature elastomers. Conversely, when industries reduce their investments and production due to economic down turn, the market could temporarily slow done.

Market competition and the presence of key players are crucial market factors influencing the High Temperature Elastomers landscape. This is because; there exist some established producers in this field who focus more on research and implementation for continuous product innovation. To strengthen their market positions, these key players usually opt for strategic partnerships, mergers as well as acquisitions. Alliances between these major corporations would enable each partner to expand its range of goods while strengthening its place within the market.

Leave a Comment