Market Analysis

In-depth Analysis of High Temperature Elastomers Market Industry Landscape

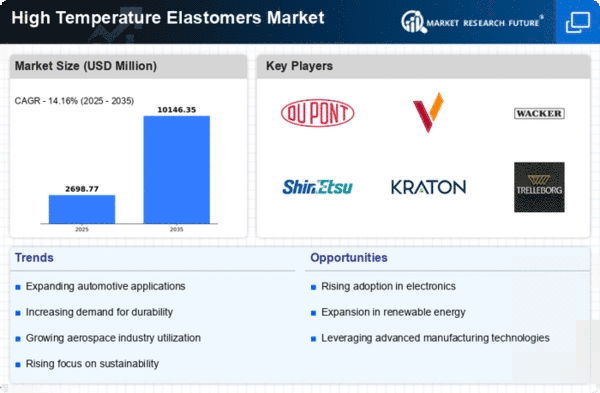

The High Temperature Elastomers Market is experiencing dynamic changes driven by several factors that shape its market dynamics. These specialized elastomers are applicable in various sectors such as automotive, aerospace, oil & gas and electronics for their capability of working under high temperatures and hostile environments among others. The increasing demand for high-performance materials that are capable of withstanding extreme temperatures without losing flexibility or durability is one of the major growth drivers in this industry.

The automobile industry acts as a driver for the market’s growth going forward. In order to increase efficiency and durability of motor vehicles automotive manufacturers require high temperature elastomer (HTE) use has increased sharply over the years. They find application in critical parts like gaskets seals hoses o-rings among others where they offer great resistance to heat chemicals and other harsh conditions faced by them. The quest for lightweight materials that exhibit superior thermal stability by automobile firms shapes how this industry behaves.

Additionally, advanced materials used in aircraft components within the aerospace sector play an important role with regard to its dynamism. In aerospace applications high temperature elastomers are integral material used in seals, gaskets and other components subjected to extreme temperatures during flight. The growing emphasis on fuel efficiency and lightweight materials within the aerospace sector is driving demand for high temperature elastomers due to the balance of weight reduction and thermal resistance.

Furthermore, the oil and gas industry drives market dynamics significantly. High temperature elastomers are essential sealing solutions for oil and gas equipment that encounter severe operating conditions such as high temperature or aggressive chemicals. Consequently, this industry compels manufacturers to develop new materials that can retain their properties under harsh environments like deep-sea drilling or high-pressure reservoirs.

Besides traditional industries, electronics has also emerged as a key factor affecting developments in the market. The use of high-temperature elastomers has increased in this sector where electronic devices have become smaller over time while at the same time there is need for performance driven materials in electronic components. These elastomers find applications on connectors, gaskets as well as other electronic materials that should operate under elevated temperatures without interfering with the functionality of a device.

Ongoing research and development activities that are aimed at making innovative high temperature elastomers with improved properties also plays a role in influencing market dynamics. Manufacturers are developing elastomers that can withstand high temperatures while being more chemically resistant, flexible and long-lasting. These advancements make the high temperature elastomers market an evolving landscape of the sector giving users much choice to choose from in order to meet their specific application needs.

The market dynamics of High Temperature Elastomers Market is driven by the different requirements of these industries including automotive, aerospace, oil & gas and electronics among others. This drives innovation through continuous efforts to develop materials able to resist extreme heat conditions yet retain their flexibility and strength. As industries change and the demand for high temperature elastomers increase, manufacturers will be well positioned to deal with challenges besides taking advantage of opportunities within this dynamic industry setting.

Leave a Comment