Growth in Food Processing Sector

The food processing sector is emerging as a vital driver for the High-Temperature Conveyor Belt Market. With the rising demand for processed foods and the need for efficient production lines, manufacturers are increasingly utilizing high-temperature conveyor belts to facilitate cooking, baking, and drying processes. These belts are designed to withstand high temperatures while maintaining food safety standards. Market analysis suggests that the food processing industry is expected to contribute significantly to the overall growth of the high-temperature conveyor belt market, with an anticipated increase in demand by 7% annually. This trend underscores the importance of specialized conveyor solutions in meeting the evolving needs of the food industry.

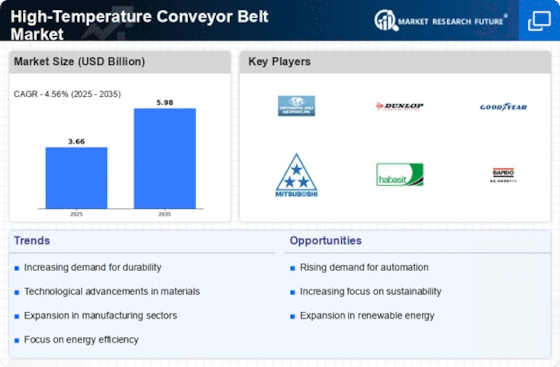

Rising Demand in Heavy Industries

The High-Temperature Conveyor Belt Market is experiencing a notable surge in demand, particularly from heavy industries such as metal processing, cement production, and glass manufacturing. These sectors require conveyor belts that can withstand extreme temperatures, often exceeding 200 degrees Celsius. As industrial activities ramp up, the need for reliable and durable conveyor systems becomes paramount. Market data indicates that the demand for high-temperature conveyor belts is projected to grow at a compound annual growth rate (CAGR) of approximately 5% over the next five years. This growth is driven by the increasing production capacities in these industries, which necessitate the use of specialized conveyor solutions to enhance operational efficiency and safety.

Expansion of Renewable Energy Sector

The expansion of the renewable energy sector is emerging as a significant driver for the High-Temperature Conveyor Belt Market. As the world shifts towards sustainable energy sources, industries such as solar and bioenergy are increasingly utilizing high-temperature conveyor systems for material handling and processing. These systems are essential for managing materials that undergo high-temperature treatments, such as biomass and solar panel components. The renewable energy sector is expected to grow at a robust pace, with estimates suggesting a CAGR of 8% over the next five years. This growth will likely create new opportunities for high-temperature conveyor belt manufacturers, as they cater to the evolving needs of this dynamic industry.

Regulatory Compliance and Safety Standards

Regulatory compliance and safety standards are becoming increasingly stringent across various industries, thereby influencing the High-Temperature Conveyor Belt Market. Companies are required to adhere to specific guidelines regarding material safety and operational efficiency, particularly in sectors such as manufacturing and food processing. High-temperature conveyor belts that meet these regulations not only ensure safe operations but also enhance productivity. As industries strive to comply with these standards, the demand for certified high-temperature conveyor belts is likely to rise. This trend may lead to a market expansion, with projections indicating a potential growth rate of 6% in the coming years as companies invest in compliant and efficient conveyor solutions.

Technological Innovations in Conveyor Systems

Technological advancements are playing a crucial role in shaping the High-Temperature Conveyor Belt Market. Innovations in materials science have led to the development of new belt compositions that offer enhanced heat resistance and durability. For instance, the introduction of advanced polymers and composite materials has improved the performance of conveyor belts under high-temperature conditions. Furthermore, the integration of smart technologies, such as sensors and monitoring systems, allows for real-time performance tracking, thereby reducing maintenance costs and downtime. As industries increasingly adopt these advanced conveyor systems, the market is expected to witness a significant transformation, with a projected increase in market size by 10% over the next few years.