Growing Focus on Energy Efficiency

The increasing emphasis on energy efficiency across various industries is driving the high-temperature composite material market. These materials offer superior thermal stability and lightweight properties, making them ideal for applications in energy generation and management. For instance, in the power generation sector, high-temperature composites are utilized in turbine components and heat exchangers, where they can withstand extreme conditions while improving overall efficiency. Market analysis suggests that the energy sector will continue to be a key contributor to the growth of the high-temperature composite material market, with a projected increase in demand as industries strive to meet sustainability goals and reduce their carbon footprint. This trend is likely to foster innovation and investment in high-performance composite solutions.

Rising Demand in Automotive Sector

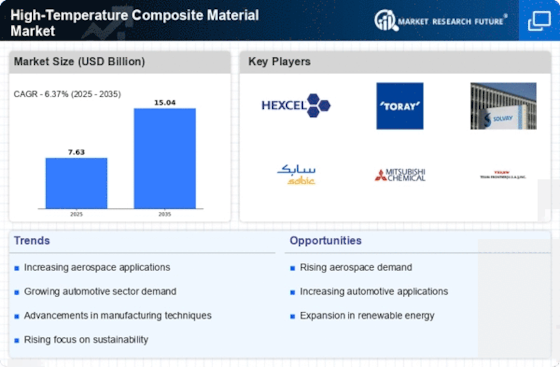

The automotive industry is increasingly adopting high-temperature composite materials due to their lightweight and high-performance characteristics. This shift is driven by the need for fuel efficiency and reduced emissions, as manufacturers seek to comply with stringent environmental regulations. The high-temperature composite material market is projected to witness substantial growth, with estimates suggesting a compound annual growth rate of over 10% in the coming years. As electric vehicles gain traction, the demand for materials that can withstand elevated temperatures without compromising structural integrity becomes paramount. Consequently, automotive manufacturers are investing in research and development to integrate these advanced materials into their production processes, thereby enhancing vehicle performance and safety.

Expansion in Aerospace Applications

The aerospace sector is a significant driver for the high-temperature composite material market, as these materials are essential for components that operate under extreme conditions. The increasing focus on fuel efficiency and performance in aircraft design has led to a surge in the use of high-temperature composites in engine components, airframes, and thermal protection systems. Market data indicates that the aerospace segment is expected to account for a substantial share of the overall market, with projections suggesting a growth rate of approximately 8% annually. This trend is further supported by advancements in manufacturing technologies, which enable the production of complex geometries and lightweight structures, thereby enhancing the overall efficiency of aircraft.

Technological Innovations in Material Science

Technological advancements in material science are propelling the high-temperature composite material market forward. Innovations such as the development of new resin systems and fiber reinforcements are enhancing the performance characteristics of these composites, making them more suitable for demanding applications. The market is witnessing a shift towards the use of advanced manufacturing techniques, such as additive manufacturing and automated fiber placement, which improve production efficiency and reduce costs. As a result, the high-temperature composite material market is expected to experience a surge in demand, particularly in sectors like aerospace and automotive, where performance and reliability are critical. The integration of smart materials that can respond to environmental changes is also on the horizon, potentially revolutionizing the industry.

Increased Investment in Research and Development

Investment in research and development is a crucial driver for the high-temperature composite material market. Companies are allocating significant resources to explore new applications and improve existing materials, aiming to enhance performance and reduce costs. This focus on R&D is particularly evident in sectors such as aerospace, automotive, and energy, where the demand for high-performance materials is escalating. Market data indicates that R&D spending in the composite materials sector is expected to rise, fostering innovation and the introduction of next-generation materials. As industries seek to leverage the benefits of high-temperature composites, the market is likely to witness a wave of new products and applications, further solidifying its position in the materials landscape.