Rising Demand in Defense Sector

The defense sector's increasing demand for advanced materials is a key driver for the high temperature-composite-resin market. As military applications require materials that can withstand extreme conditions, the need for high-performance composites is evident. The U.S. Department of Defense has allocated substantial budgets, estimated at over $700 billion annually, to enhance military capabilities, which includes the integration of high temperature-composite-resins in aircraft and armored vehicles. This trend indicates a robust growth trajectory for the market, as these materials provide superior strength-to-weight ratios and thermal stability, essential for modern defense systems. Furthermore, the emphasis on lightweight materials in military applications is likely to propel the demand for high temperature-composite-resin, thereby fostering innovation and development within the industry.

Emerging Applications in Electronics

Emerging applications in the electronics sector are becoming a notable driver for the high temperature-composite-resin market. With the increasing miniaturization of electronic devices, there is a growing need for materials that can withstand high temperatures while maintaining electrical insulation properties. High temperature-composite-resins are being utilized in the production of circuit boards and other electronic components, where thermal stability is paramount. The U.S. electronics market is projected to reach $1 trillion by 2026, and the demand for high-performance materials is expected to rise correspondingly. This trend suggests that the high temperature-composite-resin market could see a substantial increase in demand as manufacturers seek to enhance the reliability and performance of electronic devices. The integration of these advanced materials into electronics signifies a promising avenue for growth.

Expansion of Renewable Energy Sector

The expansion of the renewable energy sector is emerging as a significant driver for the high temperature-composite-resin market. As the U.S. aims to increase its renewable energy capacity, particularly in wind and solar power, the demand for durable and lightweight materials is surging. High temperature-composite-resins are increasingly utilized in the production of wind turbine blades and solar panel components due to their excellent mechanical properties and resistance to environmental degradation. The U.S. government has set ambitious targets to achieve 50% clean energy by 2030, which could potentially increase the market size for high temperature-composite-resins by an estimated $1 billion by 2026. This growth reflects the industry's adaptability and the critical role of advanced materials in supporting sustainable energy initiatives.

Technological Advancements in Manufacturing

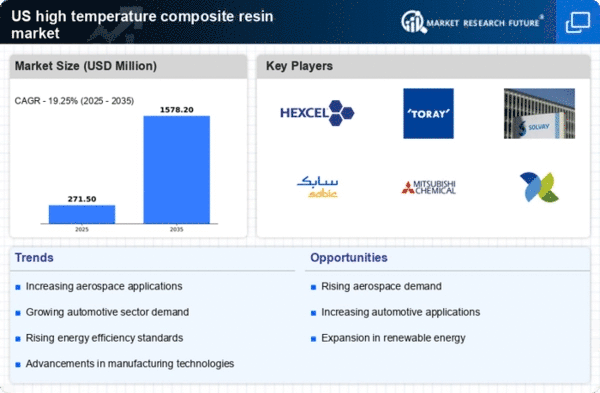

Technological advancements in manufacturing processes are significantly influencing the high temperature-composite-resin market. Innovations such as automated fiber placement and advanced resin infusion techniques are enhancing production efficiency and material performance. These technologies allow for the creation of complex geometries and reduce waste, which is crucial in meeting the growing demand from various sectors. The market is projected to grow at a CAGR of approximately 8% over the next five years, driven by these advancements. Additionally, the ability to produce high-quality composites at lower costs is likely to attract new entrants into the high temperature-composite-resin market, further stimulating competition and innovation. As manufacturers adopt these cutting-edge technologies, the overall quality and application range of high temperature-composite-resins are expected to expand.

Increased Focus on Aerospace Safety Standards

The heightened focus on aerospace safety standards is a crucial driver for the high temperature-composite-resin market. Regulatory bodies, such as the Federal Aviation Administration (FAA), are continuously updating safety regulations, necessitating the use of advanced materials that can withstand extreme temperatures and stresses. The aerospace industry is projected to invest over $200 billion in new aircraft and upgrades, which will likely include high temperature-composite-resins to enhance safety and performance. This trend indicates a growing reliance on these materials to meet stringent safety requirements, thereby driving demand within the high temperature-composite-resin market. As manufacturers strive to comply with these evolving standards, the market is expected to witness significant growth, reflecting the importance of safety in aviation.