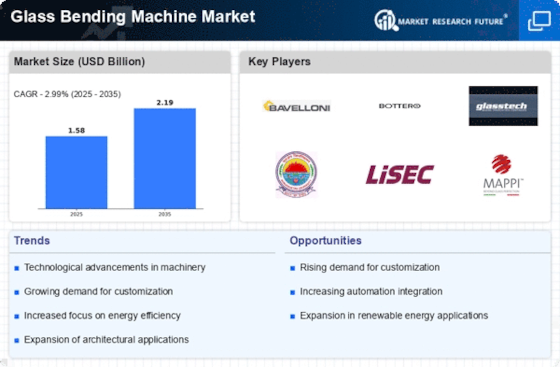

Technological Innovations

Technological advancements in glass bending machinery are significantly influencing the Glass Bending Machine Market. Innovations such as automated bending processes and enhanced precision tools are becoming increasingly prevalent. These advancements not only improve efficiency but also reduce waste, which is crucial in a competitive market. The introduction of computer numerical control (CNC) technology has revolutionized the bending process, allowing for intricate designs that were previously unattainable. As manufacturers continue to invest in research and development, the market is expected to witness a surge in demand for state-of-the-art bending machines. This trend indicates that companies that adopt these technologies may gain a competitive edge, further stimulating growth in the industry.

Rising Construction Activities

The increasing number of construction projects across various sectors appears to be a primary driver for the Glass Bending Machine Market. As urbanization accelerates, the demand for architectural glass products, which often require bending processes, is likely to rise. In 2025, the construction sector is projected to grow at a rate of approximately 5.5% annually, leading to a heightened need for advanced glass bending technologies. This trend suggests that manufacturers of glass bending machines may experience increased orders as builders seek to incorporate innovative glass designs into their projects. Furthermore, the integration of glass in modern architecture, such as facades and interiors, necessitates the use of bending machines, thereby propelling the market forward.

Customization and Aesthetic Appeal

The rising consumer preference for customized glass products is a notable driver for the Glass Bending Machine Market. As clients seek unique designs that reflect their personal style, the demand for machines capable of producing bespoke glass shapes is likely to increase. This trend is particularly evident in the automotive and interior design sectors, where tailored glass solutions are becoming more common. In 2025, the market for customized glass products is projected to grow by approximately 7%, indicating a robust opportunity for manufacturers of glass bending machines. Companies that can offer flexible and adaptable machinery to meet these customization demands may position themselves favorably in a competitive landscape.

Expansion of the Automotive Sector

The expansion of the automotive industry is emerging as a significant driver for the Glass Bending Machine Market. With the increasing incorporation of glass in vehicle designs, particularly in windshields and panoramic roofs, the demand for advanced bending machines is likely to rise. The automotive sector is expected to grow at a compound annual growth rate of around 4% in the coming years, which could translate into increased orders for glass bending machinery. This trend suggests that manufacturers who can provide specialized solutions tailored to the automotive market may experience substantial growth opportunities. As automotive designs evolve, the need for innovative glass bending technologies will become increasingly critical.

Increased Demand for Energy-Efficient Solutions

The growing emphasis on energy efficiency in construction and manufacturing processes is likely to drive the Glass Bending Machine Market. As regulations become stricter regarding energy consumption, manufacturers are compelled to adopt more sustainable practices. Energy-efficient glass bending machines not only reduce operational costs but also align with the global push towards sustainability. In 2025, it is estimated that energy-efficient technologies could account for over 30% of the market share in the glass bending sector. This shift suggests that companies focusing on developing and marketing energy-efficient solutions may find substantial opportunities for growth, as consumers increasingly prioritize sustainability in their purchasing decisions.