Increased Investment in Automation

The trend towards increased investment in automation across various sectors is significantly impacting the automated optical-inspection-system market. In Germany, companies are allocating substantial budgets to upgrade their manufacturing processes, with automation investments projected to grow by 15% annually. This shift is driven by the need for efficiency and cost reduction, as automated systems can operate continuously without fatigue. The automated optical-inspection systems play a crucial role in this transition, providing real-time feedback and reducing the reliance on manual inspections. As industries continue to embrace automation, the demand for these inspection systems is likely to surge, indicating a robust growth trajectory for the market.

Regulatory Pressures for Compliance

Regulatory pressures for compliance with industry standards are a critical driver for the automated optical-inspection-system market. In Germany, stringent regulations in sectors such as pharmaceuticals and food processing necessitate the implementation of reliable inspection systems to ensure product safety and quality. The automated optical-inspection systems provide a means to meet these regulatory requirements efficiently, reducing the risk of non-compliance penalties. As companies face increasing scrutiny from regulatory bodies, the demand for advanced inspection technologies is likely to grow. This trend underscores the importance of automated optical inspection in maintaining compliance and enhancing product integrity in highly regulated industries.

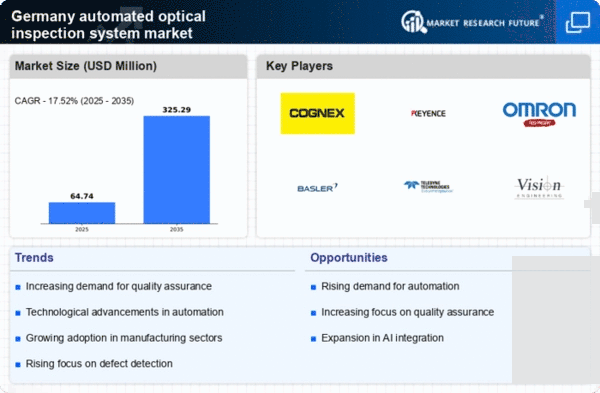

Rising Demand for Quality Assurance

The increasing emphasis on quality assurance in manufacturing processes is a key driver for the automated optical inspection system market. In Germany, industries such as automotive and electronics are under pressure to maintain high standards, leading to a growing adoption of automated inspection systems. These systems enhance defect detection rates, which can reach up to 95%, thereby reducing waste and improving overall product quality. As manufacturers strive to meet stringent quality benchmarks, the automated optical-inspection-system market is likely to experience significant growth. The integration of these systems not only ensures compliance with industry standards but also enhances operational efficiency, making them indispensable in modern production lines.

Technological Innovations in Imaging

Technological advancements in imaging technologies are propelling the automated optical-inspection-system market forward. Innovations such as high-resolution cameras and advanced image processing algorithms enable more accurate inspections, which are crucial in sectors like semiconductor manufacturing. In Germany, the market is witnessing a shift towards systems that utilize artificial intelligence and machine learning to improve defect detection capabilities. These technologies can potentially reduce inspection times by up to 30%, allowing for faster production cycles. As manufacturers seek to enhance their competitive edge, the adoption of cutting-edge imaging technologies in automated optical inspection is expected to rise, further driving market growth.

Focus on Sustainability and Waste Reduction

The growing focus on sustainability and waste reduction is emerging as a significant driver for the automated optical-inspection-system market. In Germany, manufacturers are increasingly adopting practices that minimize waste and enhance resource efficiency. Automated optical inspection systems contribute to this goal by ensuring that defective products are identified early in the production process, thereby reducing scrap rates. Reports suggest that implementing these systems can lead to a reduction in waste by up to 20%. As sustainability becomes a core component of corporate strategies, the demand for automated inspection solutions that align with these objectives is expected to rise, fostering market expansion.