Emergence of Industry 4.0

The emergence of Industry 4.0 is significantly influencing the automated optical-inspection-system market, as manufacturers embrace digital transformation and interconnected systems. This paradigm shift emphasizes the use of smart technologies, including IoT and big data analytics, to optimize production processes. The automated optical-inspection-system market is poised to benefit from this trend, as companies seek to implement real-time inspection solutions that can provide immediate feedback on product quality. The integration of these technologies is expected to enhance operational efficiency and reduce waste, aligning with the goals of Industry 4.0. As organizations increasingly adopt these advanced inspection systems, the automated optical-inspection-system market is likely to experience robust growth, driven by the demand for smarter manufacturing solutions.

Increased Focus on Safety Standards

The automated optical-inspection-system market is witnessing a heightened focus on safety standards, particularly in industries such as food and pharmaceuticals. Regulatory bodies are enforcing stringent safety regulations, compelling manufacturers to adopt advanced inspection technologies to ensure compliance. For instance, the FDA has mandated rigorous quality control measures in pharmaceutical manufacturing, which has led to an increased reliance on automated optical inspection systems. This trend is expected to drive market growth, as companies invest in technologies that can effectively monitor and verify product safety. The automated optical-inspection-system market is likely to expand as organizations prioritize compliance with safety standards, thereby enhancing consumer trust and product integrity.

Rising Demand for Quality Assurance

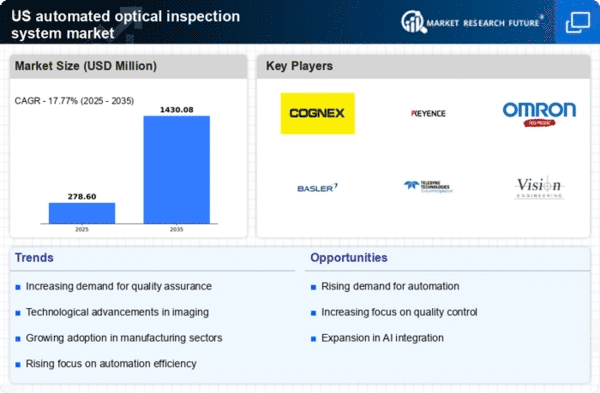

The automated optical-inspection-system market is experiencing a notable surge in demand driven by the increasing emphasis on quality assurance across various industries. As manufacturers strive to enhance product reliability and minimize defects, the adoption of automated optical inspection systems becomes essential. In the electronics sector, for instance, the market is projected to grow at a CAGR of 10% from 2025 to 2030, reflecting the industry's commitment to maintaining high standards. This trend is further supported by consumer expectations for flawless products, compelling companies to invest in advanced inspection technologies. Consequently, the automated optical-inspection-system market is positioned to benefit significantly from this heightened focus on quality, as organizations seek to implement robust inspection processes that ensure compliance with industry standards.

Integration of Artificial Intelligence

The integration of artificial intelligence (AI) into the automated optical-inspection-system market is transforming inspection processes, enhancing efficiency and accuracy. AI algorithms enable systems to learn from data, improving defect detection rates and reducing false positives. This technological evolution is particularly relevant in sectors such as automotive and pharmaceuticals, where precision is paramount. The market for AI-driven inspection systems is expected to reach $1 billion by 2027, indicating a robust growth trajectory. As companies increasingly recognize the potential of AI to streamline operations and reduce costs, the automated optical-inspection-system market is likely to see a significant uptick in adoption rates. This shift not only optimizes inspection workflows but also positions organizations to respond swiftly to quality issues, thereby enhancing overall productivity.

Growing Investment in Manufacturing Automation

The automated optical-inspection-system market is benefiting from a growing investment in manufacturing automation, as companies seek to enhance operational efficiency and reduce labor costs. The trend towards smart manufacturing, characterized by the integration of advanced technologies, is driving the demand for automated inspection solutions. In the US, the manufacturing sector is projected to invest approximately $300 billion in automation technologies by 2026, creating a favorable environment for the automated optical-inspection-system market. This investment is likely to facilitate the adoption of sophisticated inspection systems that can operate seamlessly within automated production lines. As manufacturers prioritize automation to remain competitive, the automated optical-inspection-system market is expected to experience substantial growth, driven by the need for reliable and efficient quality control mechanisms.