Expansion of Automotive Sector

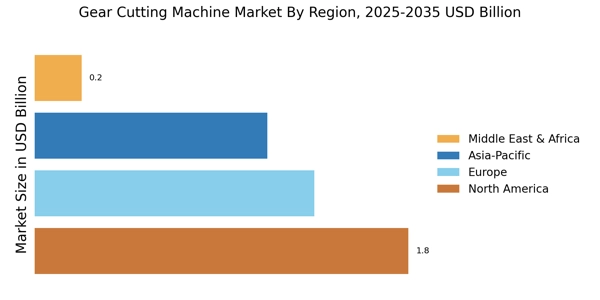

The Gear Cutting Machine Market is significantly influenced by the expansion of the automotive sector, which remains a key driver of growth. With the increasing production of vehicles, there is a corresponding rise in the demand for high-quality gears that are essential for vehicle performance and efficiency. The automotive industry is expected to witness a growth rate of around 4.5% annually, leading to an increased requirement for gear cutting machines capable of producing a diverse range of gear types. This expansion not only boosts the demand for gear cutting machines but also encourages manufacturers to innovate and enhance their production capabilities to meet the evolving needs of the automotive market.

Growth in Renewable Energy Sector

The Gear Cutting Machine Market is also positively impacted by the growth in the renewable energy sector. As the world shifts towards sustainable energy solutions, there is an increasing need for gear systems in wind turbines, solar energy systems, and other renewable technologies. The demand for precision-engineered gears in these applications is expected to rise, driven by the need for efficiency and reliability in energy production. Market forecasts indicate that the renewable energy sector could grow at a rate of 6% annually, thereby creating new opportunities for gear cutting machine manufacturers to cater to this expanding market.

Increasing Focus on Customization

The Gear Cutting Machine Market is witnessing a growing emphasis on customization and flexibility in manufacturing processes. As industries seek to differentiate their products, the demand for customized gears tailored to specific applications is on the rise. This trend necessitates the use of advanced gear cutting machines that can accommodate various design specifications and production volumes. Market Research Future reveal that the customization segment is expected to grow by approximately 7% over the next few years, indicating a shift towards more adaptable manufacturing solutions. This focus on customization not only enhances product offerings but also drives innovation within the gear cutting machine sector.

Rising Demand for Precision Engineering

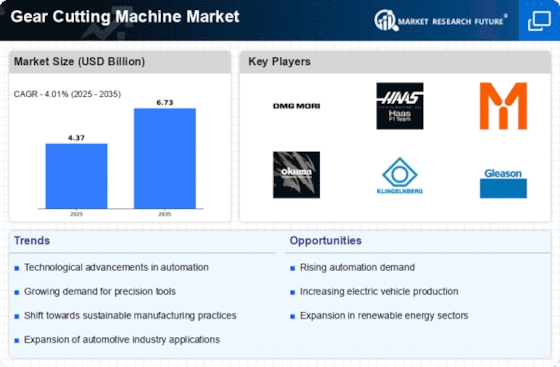

The Gear Cutting Machine Market experiences a notable surge in demand for precision engineering components across various sectors, including automotive, aerospace, and industrial machinery. As industries increasingly prioritize accuracy and efficiency, the need for advanced gear cutting machines that can produce high-quality gears with minimal tolerances becomes paramount. This trend is further supported by the growing complexity of mechanical systems, which necessitates the use of sophisticated gear designs. Market data indicates that the precision engineering sector is projected to grow at a compound annual growth rate of approximately 5.2% over the next five years, thereby driving the demand for gear cutting machines that meet these stringent requirements.

Technological Innovations in Manufacturing

Technological innovations play a crucial role in shaping the Gear Cutting Machine Market. The advent of automation, artificial intelligence, and advanced materials has transformed traditional manufacturing processes, leading to enhanced efficiency and productivity. Gear cutting machines equipped with state-of-the-art technology can perform complex operations with greater speed and accuracy, thereby reducing production costs and time. Market analysis suggests that the integration of smart technologies in manufacturing is likely to increase by 30% over the next few years, further propelling the demand for advanced gear cutting machines that can leverage these innovations to optimize production processes.