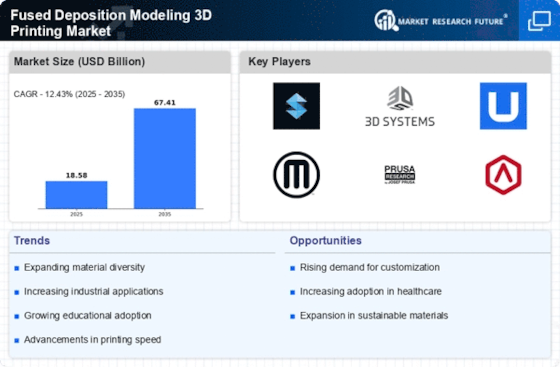

Rising Demand for Customization

The Fused Deposition Modeling 3D Printing Market is experiencing a notable surge in demand for customized products across various sectors. This trend is particularly evident in industries such as automotive and aerospace, where tailored components are essential for enhancing performance and efficiency. The ability to produce intricate designs and prototypes rapidly allows manufacturers to respond to consumer preferences more effectively. According to recent data, the customization segment is projected to grow at a compound annual growth rate of approximately 25% over the next five years. This growth is driven by the increasing need for personalized solutions, which Fused Deposition Modeling technology adeptly addresses, thereby solidifying its position in the market.

Advancements in Material Science

The Fused Deposition Modeling 3D Printing Market is witnessing rapid advancements in material science, which is enhancing the capabilities of 3D printing technologies. Innovations in thermoplastics and composite materials are enabling the production of stronger, lighter, and more durable components. This evolution is particularly beneficial in sectors such as aerospace and medical devices, where material performance is paramount. Recent studies indicate that the introduction of new materials could lead to a 15% increase in the market share of Fused Deposition Modeling technologies by 2026. As manufacturers continue to explore novel materials, the potential applications of Fused Deposition Modeling are expanding significantly.

Cost-Effectiveness of Production

Cost efficiency remains a pivotal driver in the Fused Deposition Modeling 3D Printing Market. The technology allows for reduced material waste and lower production costs compared to traditional manufacturing methods. As businesses seek to optimize their operational expenditures, the affordability of Fused Deposition Modeling becomes increasingly attractive. Reports indicate that companies utilizing this technology can achieve up to 30% savings in production costs, particularly in low-volume manufacturing scenarios. This financial advantage is compelling for startups and established firms alike, as it enables them to allocate resources more effectively while maintaining high-quality output.

Integration of Industry 4.0 Technologies

The integration of Industry 4.0 technologies is a transformative driver for the Fused Deposition Modeling 3D Printing Market. The convergence of IoT, AI, and data analytics with 3D printing processes is enhancing operational efficiency and product quality. Smart manufacturing systems that utilize Fused Deposition Modeling can optimize production schedules, reduce downtime, and improve supply chain management. Current estimates suggest that the adoption of these technologies could increase productivity in the Fused Deposition Modeling sector by up to 40% over the next few years. This integration not only streamlines operations but also positions companies to better meet the evolving demands of the market.

Sustainability and Eco-Friendly Practices

Sustainability is becoming a critical focus within the Fused Deposition Modeling 3D Printing Market. As environmental concerns escalate, manufacturers are increasingly adopting eco-friendly materials and processes. Fused Deposition Modeling technology supports the use of biodegradable filaments, which significantly reduces the carbon footprint associated with production. Furthermore, the ability to recycle materials in the printing process aligns with the growing demand for sustainable practices across industries. Market analysis suggests that the eco-friendly segment of the Fused Deposition Modeling market could expand by 20% in the coming years, reflecting a broader shift towards responsible manufacturing.