Top Industry Leaders in the Flexible Printed Circuit Board Market

*Disclaimer: List of key companies in no particular order

Competitive Landscape of the Flexible Printed Circuit Board Market

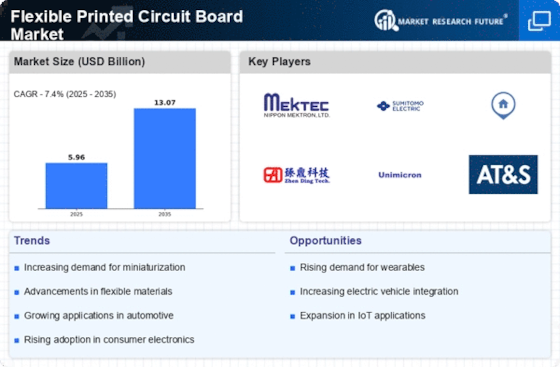

The global market for flexible printed circuit boards (FPCBs) is projected to grow rapidly in the coming years, driven by increasing demand from various industries such as consumer electronics, automotive, medical, and aerospace. This growth has attracted a diverse range of players, creating a competitive landscape where established companies and new entrants are vying for market share.

Some of the Flexible Printed Circuit Board companies listed below:

- Nitto Denko Corporation

- Zhen Ding Tech

- bhflex Co. Ltd.

- Interflex Co. Ltd.

- Career Technologies

- MFS Technology

- Flexible Circuit

- Daeduck GDS Co. Ltd.

- Sumitomo Electric Industries Ltd.

- Fujikura Ltd

Strategies Adopted by Key Players:

- Product Portfolio Expansion: Broadening their product portfolio to cater to the diverse needs of various industries and applications.

- Focus on Innovation: Investing in research and development to create next-generation FPCBs with improved performance and functionality.

- Geographic Expansion: Expanding their reach into new geographic markets with high growth potential.

- Strategic Partnerships: Collaborating with other companies in the ecosystem to access new technology, resources, and markets.

- Mergers and Acquisitions: Engaging in mergers and acquisitions to consolidate market share and gain access to new technologies or markets.

Factors for Market Share Analysis:

- Product Breadth and Depth: The breadth and depth of the FPCB product portfolio offered, covering different technologies, materials, and functionalities.

- Technological Expertise: The company's ability to develop and manufacture innovative FPCBs with advanced features and performance characteristics.

- Manufacturing Capabilities: The company's production capacity, quality control processes, and ability to meet customer requirements efficiently.

- Cost Competitiveness: The company's ability to offer competitive prices for its FPCBs while maintaining high quality standards.

- Customer Service and Support: The company's reputation for providing excellent customer service and support to its customers.

- Financial Strength: The company's financial stability and resources to invest in research and development, market expansion, and acquisitions.

The competitive landscape of the FPCB market is characterized by a mix of established players and new entrants. Established players have a strong brand reputation, extensive experience, and global reach. However, new entrants are bringing innovative technologies and competitive pricing strategies to the market. This creates a dynamic environment where companies need to continuously innovate, adapt to changing market demands, and build strong customer relationships to succeed.

Latest Company Updates:

September 2023- Panasonic has created a novel material for the flexible printed circuit board which can be utilized for creating meta-surface designs for the 6G radio applications along with lightweight designs and wearables. The CSS or the copper clad stretch flexible printed circuit technology created by Panasonic in fact can be stretched as opposed to conventional copper clad laminates. Besides, the same resin system has been used both for the insulative coverlay and the circuitry layer.

May 2023- Mitsubishi Electric’s ME Innovation Fund recently has invested in Elephatec Inc., a startup printed circuit board manufacturer in Tokyo, Japan as part of the 900-million-yen funding round. Elephantec mass manufactures PCBs utilizing metal inkjet printing. The company is coming to the market with the mission in sustainable and eco-friendly manufacturing and it utilizes its metal inkjet printing & copper plating technologies for manufacturing and selling P-Flex flexible printed circuit boards. The manufacturing method is known as Pure Additive. This additive metal inkjet printing technology enables metal in being printed on the substate where necessary only.

August 2022- InnovationLab, leading printed electronics company has reported a revolution in the additive creation of printed circuit boards. This German company & ISRA Vision, its partner innovative technology company have created a manufacturing procedure for the copper-based solderable circuits which meets the higher environmental standards and cutting costs. These circuits are in fact screen-printed as well as compatible with the conventional reflow process. This process also aids in reducing material consumption and also consequently waste as the substrates utilized in the additive PCB manufacturing are about 15 times thinner over those utilized in conventional processes.