Market Share

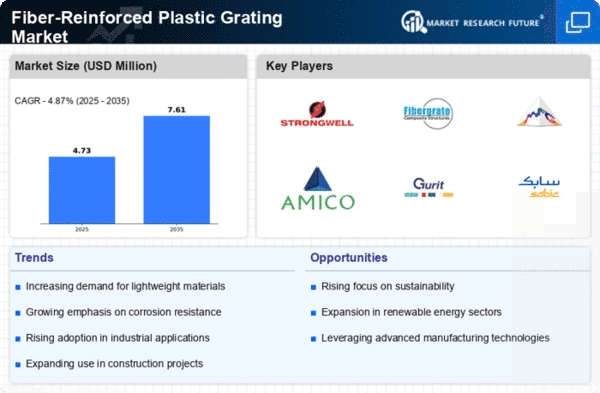

Fiber-Reinforced Plastic Grating Market Share Analysis

In the competitive realm of the Fiber-Reinforced Plastic (FRP) Grating Market, companies employ diverse strategies to establish their market share and gain a competitive advantage. One notable strategy is differentiation, where companies highlight unique characteristics of their FRP grating products. This may involve emphasizing features such as high strength, corrosion resistance, or specific designs tailored for industries such as oil and gas, chemical processing, or water treatment. By showcasing these distinctive attributes, companies aim to stand out in the market and attract customers seeking specialized FRP grating solutions for their specific applications.

Cost leadership is another significant strategy within the FRP Grating Market. Companies focus on optimizing production processes, negotiating favorable raw material prices, and achieving economies of scale to become low-cost producers. By offering competitive prices for FRP grating products, companies adopting this strategy aim to appeal to cost-conscious customers and gain a competitive edge. Cost leadership not only helps attract customers but also acts as a barrier for potential competitors seeking to match the affordability of FRP grating products.

Market segmentation plays a crucial role in the FRP Grating Market, involving the customization of products to meet the specific needs of different industries. Companies analyze the varied requirements in sectors such as marine, industrial, and construction. They then tailor their FRP grating solutions to address these specific needs effectively. This strategy enables companies to penetrate various market segments and build a robust presence in each, thereby expanding their overall market share.

Innovation is a key driver in market share positioning within the FRP Grating Market. Companies invest in research and development to introduce new materials, improve manufacturing processes, or discover novel applications for FRP grating. By staying at the forefront of technological advancements, companies position themselves as leaders, attracting customers seeking advanced FRP grating solutions that meet the evolving demands of various industries. This innovation-driven strategy allows companies to differentiate themselves and stay ahead of the competition.

Strategic collaborations and partnerships are gaining prominence in the FRP Grating Market's market share positioning. Companies form alliances with suppliers, distributors, or research institutions to enhance their market presence. Collaborations can lead to improved supply chain efficiency, access to new markets, and shared knowledge on technological advancements and market trends. By leveraging the strengths of their partners, companies strategically position themselves for sustained growth and an increased market share.

Geographical expansion is a notable strategy in the FRP Grating Market. Companies identify and enter untapped markets, either domestically or internationally, to broaden their customer base. This involves understanding regional demands, adapting products to local specifications, and navigating diverse regulatory landscapes. By expanding their geographical reach, companies can capitalize on diverse market opportunities and establish themselves as key players in the global FRP grating market, enhancing their overall market share.

Leave a Comment