-

EXECUTIVE SUMMARY

-

MARKET INTRODUCTION

-

Definition

-

Scope of the Study

- Research Objective

- Assumptions

- Limitations

-

RESEARCH METHODOLOGY

-

Overview

-

Data Mining

-

Secondary Research

-

Primary Research

- Primary Interviews and Information Gathering Process

- Breakdown of Primary Respondents

-

Forecasting Model

-

Market Size Estimation

- Bottom-Up Approach

- Top-Down Approach

-

Data Triangulation

-

Validation

-

MARKET DYNAMICS

-

Overview

-

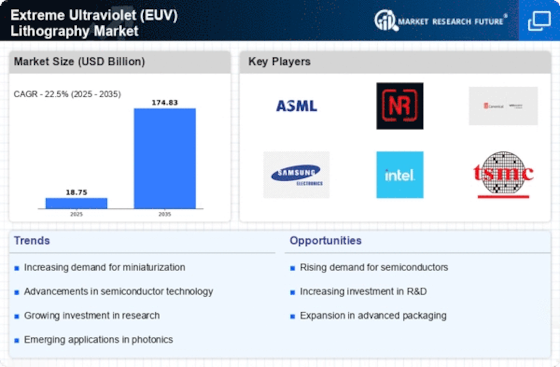

Drivers

-

Restraints

-

Opportunities

-

MARKET FACTOR ANALYSIS

-

Value Chain Analysis

-

Porter’s Five Forces Analysis

- Bargaining Power of Suppliers

- Bargaining Power of Buyers

- Threat of New Entrants

- Threat of Substitutes

- Intensity of Rivalry

-

COVID-19 Impact Analysis

- Market Impact Analysis

- Regional Impact

- Opportunity and Threat Analysis

-

GLOBAL EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY EQUIPMENT

-

Overview

-

Light Source

-

Opitcs

-

Mask

-

Others

-

GLOBAL EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market, BY END USER

-

Overview

-

Integrated Device Manufacturer (IDM)

-

Foundries

-

GLOBAL EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market, BY REGION

-

Overview

-

North America

- US

- Canada

-

Europe

- Germany

- France

- UK

- Italy

- Spain

- Rest of Europe

-

Asia-Pacific

- China

- India

- Japan

- South Korea

- Australia

- Rest of Asia-Pacific

-

Rest of the World

- Middle East

- Africa

- Latin America

-

COMPETITIVE LANDSCAPE

-

Overview

-

Competitive Analysis

-

Market Share Analysis

-

Major Growth Strategy in the Global Extreme Ultraviolet (EUV) Lithography Market,

-

Competitive Benchmarking

-

Leading Players in Terms of Number of Developments in the Global Extreme Ultraviolet (EUV) Lithography Market,

-

Key developments and Growth Strategies

- New ProductLaunch/Service Deployment

- Merger &Acquisitions

- Joint Ventures

-

Major Players Financial Matrix

- Sales & Operating Income,2024

- Major Players R&D Expenditure.2024

-

COMPANY PROFILES

-

NIKON CORPORATION

- Company Overview

- Financial Overview

- Products Offered

- Key Developments

- SWOT Analysis

- Key Strategies

-

CANNON INC.

- Company Overview

- Financial Overview

- Products Offered

- Key Developments

- SWOT Analysis

- Key Strategies

-

ASML

- Company Overview

- Financial Overview

- Products Offered

- Key Developments

- SWOT Analysis

- Key Strategies

-

APPENDIX

-

References

-

Related Reports

-

-

LIST OF TABLES

-

GLOBAL EXTREME ULTRAVIOLET (EUV) LITHOGRAPHY MARKET, SYNOPSIS, 2018-2032

-

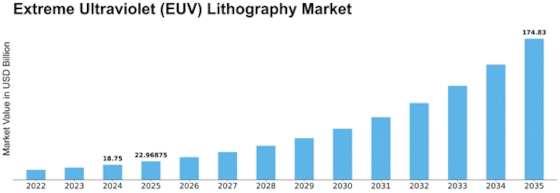

GLOBAL EXTREME ULTRAVIOLET (EUV) LITHOGRAPHY MARKET, ESTIMATES &FORECAST, 2018-2032(USD BILLION)

-

GLOBAL EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY EQUIPMENT, 2020-2034(USD BILLION)

-

GLOBAL EXTREME ULTRAVIOLET (EUV) LITHOGRAPHY MARKET, BYEND USER, 2020-2034(USD BILLION)

-

NORTH AMERICA: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY EQUIPMENT, 2020-2034(USD BILLION)

-

NORTH AMERICA: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY END USER,2020-2034(USD BILLION)

-

US: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY EQUIPMENT, 2020-2034(USD BILLION)

-

US: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY END USER,2020-2034(USD BILLION)

-

CANADA: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY EQUIPMENT, 2020-2034(USD BILLION)

-

CANADA: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY END USER,2020-2034(USD BILLION)

-

EUROPE: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY EQUIPMENT, 2020-2034(USD BILLION)

-

EUROPE: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY END USER,2020-2034(USD BILLION)

-

GERMANY: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY EQUIPMENT,2020-2034(USD BILLION)

-

GERMANY: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY END USER,2020-2034(USD BILLION)

-

FRANCE: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY EQUIPMENT, 2020-2034(USD BILLION)

-

FRANCE: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY END USER,2020-2034(USD BILLION)

-

ITALY: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY EQUIPMENT, 2020-2034(USD BILLION)

-

ITALY: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY END USER,2020-2034(USD BILLION)

-

SPAIN: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY EQUIPMENT, 2020-2034(USD BILLION)

-

SPAIN: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY END USER,2020-2034(USD BILLION)

-

UK: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY EQUIPMENT, 2020-2034(USD BILLION)

-

UK: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY END USER, 2020-2034(USD BILLION)

-

REST OF EUROPE: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY EQUIPMENT, 2020-2034(USD BILLION)

-

REST OF EUROPE: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY END USER,2020-2034(USD BILLION)

-

ASIA-PACIFIC: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY EQUIPMENT, 2020-2034(USD BILLION)

-

ASIA-PACIFIC: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY END USER,2020-2034(USD BILLION)

-

JAPAN: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY EQUIPMENT, 2020-2034(USD BILLION)

-

JAPAN: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY END USER,2020-2034(USD BILLION)

-

CHINA: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY EQUIPMENT, 2020-2034(USD BILLION)

-

CHINA: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY END USER,2020-2034(USD BILLION)

-

INDIA: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY EQUIPMENT, 2020-2034(USD BILLION)

-

INDIA: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY END USER,2020-2034(USD BILLION)

-

AUSTRALIA: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY EQUIPMENT, 2020-2034(USD BILLION)

-

AUSTRALIA: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY END USER,2020-2034(USD BILLION)

-

SOUTH KOREA: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY EQUIPMENT, 2020-2034(USD BILLION)

-

SOUTH KOREA: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY END USER,2020-2034(USD BILLION)

-

REST OF ASIA-PACIFIC: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY EQUIPMENT, 2020-2034(USD BILLION)

-

REST OF ASIA-PACIFIC: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY END USER,2020-2034(USD BILLION)

-

REST OF THE WORLD: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY EQUIPMENT, 2020-2034(USD BILLION)

-

REST OF THE WORLD: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY END USER,2020-2034(USD BILLION)

-

MIDDLE EAST: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY EQUIPMENT, 2020-2034(USD BILLION)

-

MIDDLE EAST: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY END USER,2020-2034(USD BILLION)

-

AFRICA: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY EQUIPMENT, 2020-2034(USD BILLION)

-

AFRICA: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY END USER,2020-2034(USD BILLION)

-

LATIN AMERICA: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY EQUIPMENT, 2020-2034(USD BILLION)

-

LATIN AMERICA: EXTREME ULTRAVIOLET (EUV) Extreme Ultraviolet EUV Lithography Market,BY END USER,2020-2034(USD BILLION)

-

LIST OF FIGURES

-

RESEARCH PROCESS

-

MARKET STRUCTURE FOR THE GLOBAL EXTREME ULTRAVIOLET (EUV) LITHOGRAPHY MARKET

-

MARKET DYNAMICS FOR THE GLOBAL EXTREME ULTRAVIOLET (EUV) LITHOGRAPHY MARKET

-

GLOBAL EXTREME ULTRAVIOLET (EUV) LITHOGRAPHY MARKET, SHARE (%), BY EQUIPMENT, 2024

-

GLOBAL EXTREME ULTRAVIOLET (EUV) LITHOGRAPHY MARKET, SHARE (%), BY END USER,2024

-

GLOBAL EXTREME ULTRAVIOLET (EUV) LITHOGRAPHY MARKET, SHARE (%), BY REGION, 2024

-

NORTH AMERICA: EXTREME ULTRAVIOLET (EUV) LITHOGRAPHY MARKET, SHARE (%), BY REGION, 2024

-

EUROPE: EXTREME ULTRAVIOLET (EUV) LITHOGRAPHY MARKET, SHARE (%), BY REGION, 2024

-

ASIA-PACIFIC: EXTREME ULTRAVIOLET (EUV) LITHOGRAPHY MARKET, SHARE (%), BY REGION, 2024

-

REST OF THE WORLD: EXTREME ULTRAVIOLET (EUV) LITHOGRAPHY MARKET, SHARE (%), BY REGION, 2024

-

GLOBAL EXTREME ULTRAVIOLET (EUV) LITHOGRAPHY MARKET: COMPANY SHARE ANALYSIS, 2024 (%)

-

NIKON CORPORATION: FINANCIAL OVERVIEW SNAPSHOT

-

NIKON CORPORATION: SWOT ANALYSIS

-

CANNON INC.:FINANCIAL OVERVIEW SNAPSHOT

-

CANNON INC.:SWOT ANALYSIS

-

ASML:FINANCIAL OVERVIEW SNAPSHOT

-

ASML:SWOT ANALYSIS

Leave a Comment