Market Trends

Key Emerging Trends in the Ethylene Tetrafluoroethylene (ETFE) Market

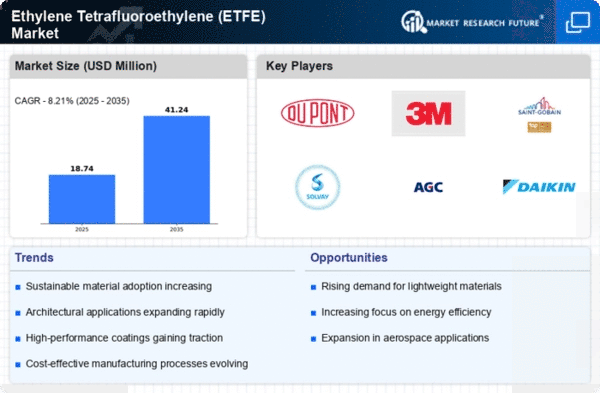

The global chemical industry has huge changes that have occurred in the recent past, including in Ethylene Tetrafluoroethylene (ETFE) Market. In sectors such as automotive construction and electrical fields, ETFE which is a high-performance polymer famous for its excellent thermal and chemical resistance has been applied diversely. A striking trend in this market involves the use of ETFE for these purposes especially being used to construct iconic buildings or structures facing a green building challenge; architects and engineers prefer it because it is light weight, ductile and transmits natural light thereby offering innovative designs as well as energy saving options.

Additionally, the automotive sector has emerged as one of the key growth drivers within the ETFE market today. It can be used as an ideal choice for automobile parts due to its unique combination of properties like high chemical resistance, great electrical insulation, low frictional force among others. Henceforth, due to continual lightweighting efforts besides electrification focus within the automotive industry ETFT demand will substantially increase thereby boosting markets upwards movement. Furthermore, increased adoption of electric vehicle components made from ETFE emanates from growing trends towards sustainability and eco-friendliness.

ETFE wires and cables have gained popularity in electrical applications due to their distinctive characteristics globally. Reliable performance coupled with guaranteed longevity makes this material suitable for various electrical uses given its good electric insulation feature. Thus far with electronic advancements continuing while energy sector expands daily also leading to increased demand for quality electrical components consequently pushing forward the growth of ETFE’s Marketing department.

Another trend observed in the ETFE market is the focus on research and development to enhance its properties and expand its application scope. Material performance characteristics such as mechanical strength, chemical resistance, and thermal stability are some of the key areas where manufacturers invest in technological innovations in order to improve the performance of this material. This ongoing innovation has given an opportunity for ETFE to be accepted within industries like aerospace due to its lightweight/durable nature.

Regarding geography, Asia Pacific has been a major player especially after gaining popularity in this market. China and India have been leading countries that have seen an increase in industrialization, infrastructure development and manufacturing activities thereby prompting demand for ETFE mainly used for constructional purposes amongst others. The region’s rapid economic growth coupled with urbanization has necessitated the need for advanced materials hence making it a vital part of growing markets at large.

Leave a Comment