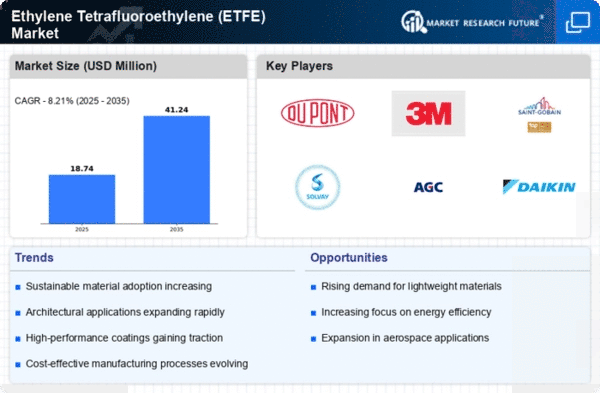

Top Industry Leaders in the Ethylene Tetrafluoroethylene (ETFE) Market

Ethylene Tetrafluoroethylene (ETFE), a high-performance fluoropolymer, is experiencing a surge in demand across diverse industries due to its unique properties like chemical resistance, weatherability, and lightweight nature. This has ignited a dynamic competitive landscape in the ETFE market, with established players and emerging entrants vying for a larger share. Understanding the strategies, market dynamics, and recent developments is crucial for anyone navigating this thriving space.

Market Share Drivers: A Multifaceted Game

The key factors influencing market share in the ETFE landscape are:

-

Product Differentiation: Offering unique formulations, tailored solutions, and sustainable production processes can set players apart. Companies like Asahi Glass Co. (AGC) and Daikin Industries are leading the charge with innovative ETFE films and coatings. -

Regional Focus: Asia-Pacific, particularly China, is the fastest-growing market due to its booming infrastructure and automotive sectors. Capturing regional nuances and establishing strong distribution networks is vital. Solvay, with its strategic partnerships in China, is a prime example. -

Vertical Integration: Controlling the entire value chain, from raw materials to finished products, can give companies a cost advantage and greater control over quality. Zeus Industrial Products, a US-based leader, exemplifies this approach. -

Technological Advancements: Investing in R&D to develop new applications and processing techniques can unlock new market segments. Companies like DuPont are pushing the boundaries with ETFE composites and membranes.

Strategies in Play: A Kaleidoscope of Approaches

Players in the ETFE market are employing diverse strategies to gain an edge:

-

Acquisitions and Mergers: Merging with or acquiring smaller players with specific expertise or regional presence can accelerate growth. BASF's acquisition of Chemours' fluoroproducts business is a recent example. -

Partnerships and Collaborations: Collaborating with universities, research institutes, and other industry players can foster innovation and expand market reach. AGC's partnership with the Fraunhofer Institute for Chemical Technology is a case in point. -

Sustainability Focus: Highlighting the environmental benefits of ETFE, such as its recyclability and long lifespan, can resonate with eco-conscious consumers. Daikin Industries' focus on bio-based ETFE production is a noteworthy strategy. -

Digitalization: Leveraging digital tools for process optimization, customer relationship management, and e-commerce can improve efficiency and reach. Solvay's implementation of digital marketing and customer portals is a prime example.

Key Players

3M (US), AGC Inc. (Japan), Hubei Everflon Polymer CO., Ltd. (China), DAIKIN INDUSTRIES, Ltd. (Japan), Vector Foiltec. (Germany), DuPont de Nemours, Inc. (US), Li Chang Technology (Ganzhou) Co., Ltd. (China), and Ensinger (Germany).

Recent News:

Vector Foiltech’s Texlon ETFE finds an ideal home at Pavilion Bukit Jalil located in Kuala Lumpur, where it had been installed by January 2021. The enormous canopy covers a large open area at Bukit Jalil Mall, Kuala Lumpur. Thus, instead of being outside space alone, it is converted into an event place whereby concerts are held together with fashion shows on the sides. It links with the complex, effectively shielding visitors from harsh weather throughout all four seasons. The total surface covered by Texlon® ETfE amounts to approximately six thousand nine hundred fifty square meters.

SoFi Stadium is located in Los Angeles County and has room for seating seventy thousand two hundred forty football fans; its roof was reinforced with AGC Fluon ETFE fluoropolymer films in November 2020.

In March 2020, Tokyo International Airport will be renovated completely. The international Terminal 2 has reopened for business. The revolutionary roofing material chosen was AGC Fluon ETFE Film, which was installed in over nine thousand square meters of the surface. The lightweight Fluon ETFE film allows less amount of structural steel to be used compared with more traditional roofing materials, hence leading to a lighter weight and an overall appealing look.