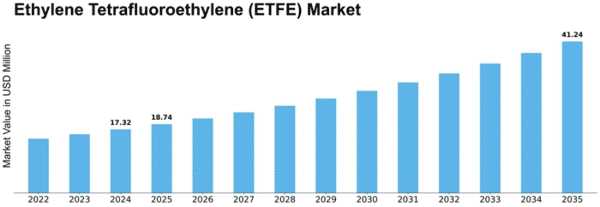

Ethylene Tetrafluoroethylene Etfe Size

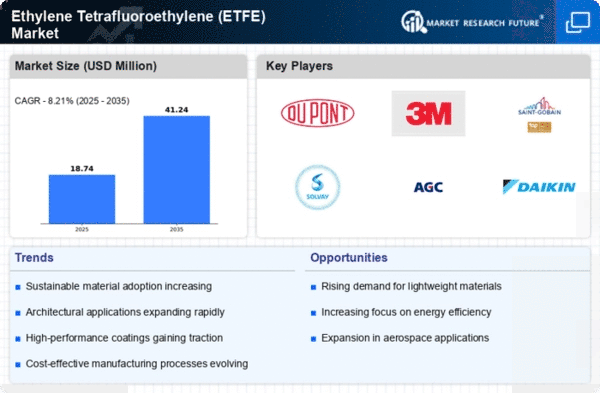

Ethylene Tetrafluoroethylene (ETFE) Market Growth Projections and Opportunities

The dynamics and growth path of the Ethylene Tetrafluoroethylene (ETFE) market are influenced by several factors. The ETFE market is driven by increasing demand for strong and lightweight materials used in various industries. ETFE, which has a great strength to weight ratio, is becoming popular in the construction and automobile industry. Among other things, the transparency of ETFE which allows natural light into buildings while enabling insulating and resistance to environmental conditions makes it preferred by constructors.

In addition, ETFE chemical resistance properties make it an ideal material for pipes and tubes used in aggressive chemicals transportation manufacturing. This application diversifies use of this material into chemical processing sector thereby increasing its demand on the market. Other than that, excellent thermal and electrical insulation qualities allow for the utilization of ETFE in wire and cable based applications thus boosting overall expansion of business.

Initiatives across the world have been promoting sustainability practices as well as green technologies through regulations which significantly impact on ETFE market shaping process. Recyclability as well as eco-friendliness aspect becomes a major concern when selecting materials since governments alongside industries aim at reducing their carbon footprints. Consequently; architects together with designers including it in their sustainable building projects drive up demand for this product hence contributing towards expansion scope.

The aerospace sector also plays an important role in influencing the growth of the ETFE market. Its low density coupled with high resistance to extreme temperatures make it suitable for use in aircraft components, a trend that further drives its market growth. Additionally, rise in air travel needs has led to an increase aviation industry’s requirement of lightweight yet durable materials like ETFEs thus propelling its demand.

Geopolitics also affects ETFE markets especially regarding availability pricing raw materials geopolitics . Ethylene; one of such commodities needed during production processes experiences changes within petrochemical due to oil prices and political differences among countries et cetera . As such, these are the drivers which major industry players closely follow to adapt their strategies and keep up with emerging risks thereby clearly depicting a link that exists within global market of ETFEs.

Moreover, even from its infancy stage, the ETFE market has been growing tremendously due to competitive forces. Product quality, innovations as well as low-costing policies are some of the paths that big market players like to go through in order to differentiate themselves in this business. This creates an environment where there exist constant pressure to compete, hence leading to changes in the way businesses operate.

Leave a Comment