Market Trends

Key Emerging Trends in the Epoxy Coatings Market

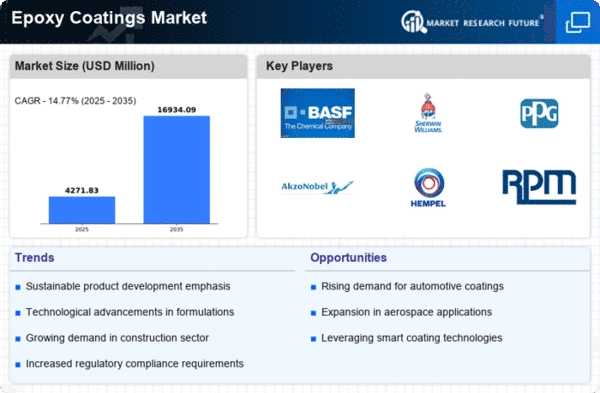

The trends on the market with the epoxy coatings describe a dynamic business environment, which can be attributed to the increasing application in different industries, including the coating market. Epoxy coatings, due to their properties like strong adhesion, dependability, and chemical as well as abrasion resistance are being adopted for use in different situations like construction, cars, and industrial processing. One of the most important tendencies in the epoxy coatings market is the rate of demand from the construction industry. Because of construction maximization on the planetary scale and epoxy coating is broadly used for flooring, infrastructure protection, and corrosion prevention while it enhances the market size.

Additionally, the auto sector has contributed immensely in setting the market pattern of epoxy coatings. With the car makers dedicating their efforts towards improving the vehicle appearance, durability, and corrosion resistance, consequently, epoxy paints used in automotive parts like chassis, underbodies, and engine components becomes more popular. It is believed that this trend will take place as long as the automotive industry is developing and ensuring that the coatings are of high quality in order to extend the life time of vehicles.

The environmental factors have also acted as catalysts in the market, and the outstanding trend is the development of ecological epoxy coatings. In line with the growing interest in sustainability, manufacturers are prioritizing investments in formulations that exclude or significantly cut down the concentrations of volatile organic compounds (VOCs) and hazardous materials. Correspondingly, global approaches to encourage ecological responsiveness are implemented, thereby, dictating companies and consumers to be environmentally conscious in purchasing these coatings.

An electronic industry is one other vital player in the trends of the epoxy coatings market. As electronic devices become more complex and miniature, ecoatings epoxy serves the purpose of encapsulation and of the protection of delicate components. Epoxy paint coatings that shield circuits from moisture, dust and surroundings attributes cause to the longevity of the electronics.

Besides, the energy sector is being led by epoxy coatings to different applications such as pipelines, tanks, and offshore structures. This type of coating protects the industry from corrosion and, in this way, enhances the preservation of the key energy infrastructure. With the whole world continually working to ensure sustainability and renewable energy sources, the market for protective and coating materials in this sector is expected to be growing strongly.

Globalization additionally determines market patterns, caused by the changes in supply-chain dynamics and the enemy strategies in the epoxy coatings market. The manufacturers are strengthening their presence in the global arena through market expansions and forming strategic alliances with other players in the market in order to serve multi-country customers with various tastes and preferences.

Leave a Comment