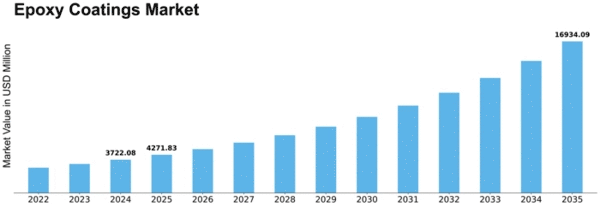

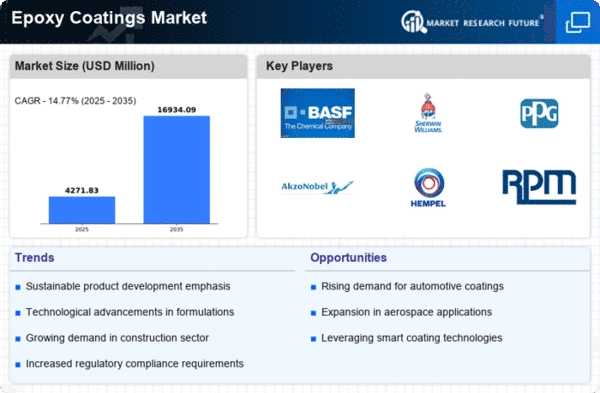

Epoxy Coatings Size

Epoxy Coatings Market Growth Projections and Opportunities

Epoxy Coatings market works under the influence of various market influencing factors, all of which jointly determine its dynamics. Among the significant factors is the ever-rising demand emanating from different application bases such as building & construction, transport, and electrical engineering. While the sectors are rising, the demand for securing and enduring surface coatings that, for instance, are epoxy coatings, rises hand in glove as well. The construction sector is one of the industries that need epoxy paints the most because of its wide range of protective functions such as preventing corrosion, abrasion, and chemical attack.

Besides the normal regulatory concerns, regulatory frameworks have a major role to play in the Epoxy Coating market. Strict environmental restrictions are set up to lower the content of VOCs and to comply with the practices that are sustainable, which has an effect on the formulation and application of epoxy coatings as well. Raw material makers of the industry also must follow the environmental standards, making sure that VOC-free or eco-friendly epoxy coatings are developed to comply with the regulations as well as the rising demand for green coatings.

In addition to economic trends on the global arena the Epoxy Coatings market is gaining popularity. Economic growth in emerging markets, industrialization, and infrastructure constructions generate leaps of demands for epoxy coatings in the construction and manufacturing sectors chiefly of all. While an economy slump could affect epoxy coatings market performance in the short term, as fewer construction works and industrial output are happening so the demand for epoxy coatings will be reduced.

Innovation and new technologies are invaluable drivers in Epoxy coatings market. Constant research and development process of creating new formulations and improving existing ones result in the contribution of enhanced curing times, better adhesion properties and an increased capacity of survive harsh environmental conditions. The organizations enjoying the fruits of innovation become more competitive due to offering world-class performance products that meet prospective customers' changing needs and various application domains.

Raw material prices and volumes are key factors which determine the market size of Epoxy coatings. These coatings often involve epoxy resins which are a derived from petrochemical base. Up and down movements in the key input, crude oil cost, is one of the factors influencing the overall production cost for epoxy coatings. However, the availability of raw materials and the removal of any disruptions in the logistics will serve to increase the production capacity and may cause the changes in pricing and the market behavior.

Another important variable influencing the market conditions is the level of competitive pressure. Along with many players, either big or small, manufacturers compete intensely. One of the ways is to vary their products by quality, performance, or pricing. In this market, strategic partnerships, mergers, and acquisitions are essential tools to enterprises which are trying to advance their range of products, strengthen their technological products, and improve their market position.

Leave a Comment