Market Analysis

In-depth Analysis of Epoxy Coatings Market Industry Landscape

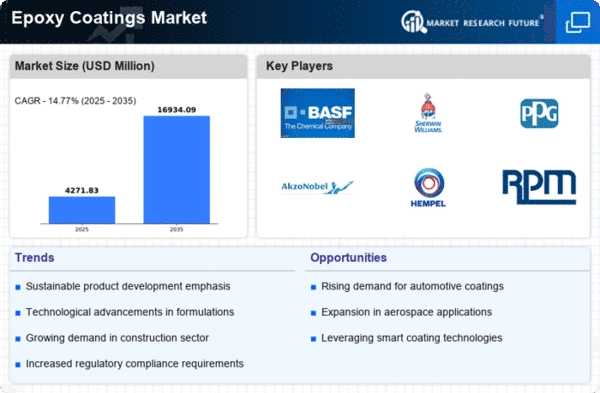

The market dynamics of epoxy coatings are highly sensitive to the influences of a few key factors that either drive or limit the demand, growth, or competitive dynamics of these products. The main factor together with the use all over industries of epoxy paints as a result of their superior adhesion unique and durability. Epoxy coatings are the coatings that have the characteristics forming a strong protective layer on surfaces which makes them to resist corrosion, chemicals, and wear. Due to this flexibility, epoxy coatings are considered as a first-choice option in such areas as heavy industrial flooring, as well as protection for metal and concrete constructions.

Construction and Infrastructure sectors are the prime fields boosting epoxy coatings market. Urbanization and industrialization are expanding fast on a global scale while they appear new demands for corrosion-resistant and weather protecting coatings that ensure infrastructure integrity and extension of service life. More often than ever epoxy coatings, which offer an excellent resistance to various abuses, are used in construction to give protection to flooring, bridges and also waterproofing.

Environmental parameters as well make a summing impact on the epoxy coatings market trends With tighter regulations for VOC emissions, the water-based and low-VOC epoxy coatings are now encouraged in the market. Nowadays, manufacturers pay their utmost attention to and the if it meets the regulators and if it also addresses the growing request for the better and the sustainable solution.

The global economic landscape plays a major role along with other market movement affecting the epoxy coatings market. Volatility in the global economy, currency rates fluctuations and geopolitical disturbs can affect the prices for raw materials, labor and production costs shifting strategies and competitiveness in the market. Many epoxy coatings producers carefully watch these economic indicators to make the decisions on a business level and keep being able to adapt to a rather dynamic market.

Technological breakthroughs are basically the ones that determine how epoxy coatings market is evolving. Last but not least, the introduction of new formulations through research and development, ranging from self-healing to anti-microbial epoxy coatings. The emergence of these innovations is not merely a response to the evolving customer requirements but the advancements are also catalysts of growth and competitiveness in epoxy coatings industry.

The competitive market of epoxy coatings is dictated by strategic alliances, conglomerations, and takeovers of the leading players in the industry. Companies are in the position to avail themselves of each other's capabilities jointly, to increase their products variety, and broaden their market share. These instrumental shifts aid the enhancement of the epoxy coatings industry, which ultimately leads to more market performance and competitiveness.

Leave a Comment