Sustainability Initiatives

Sustainability initiatives are becoming a pivotal driver in the Electron Beam Physical Vapor Deposition Market. As industries face increasing pressure to reduce their environmental footprint, EBPVD offers a more sustainable alternative to traditional deposition methods. The process generates minimal waste and utilizes less energy, aligning with global sustainability goals. Moreover, the ability to recycle materials used in EBPVD processes contributes to a circular economy, appealing to environmentally conscious consumers and businesses. Companies are investing in EBPVD technologies to enhance their sustainability profiles, which is likely to attract new customers and retain existing ones. This shift towards sustainable practices is expected to bolster market growth, with projections indicating a potential increase in market size by 15% over the next decade.

Growth in Electronics Sector

The Electron Beam Physical Vapor Deposition Market is significantly influenced by the growth in the electronics sector. With the proliferation of consumer electronics, there is an escalating need for high-performance materials that can enhance device functionality. EBPVD is increasingly utilized in the production of semiconductors, displays, and other electronic components due to its ability to create thin films with exceptional uniformity and adherence. The electronics market is projected to reach a valuation of over 1 trillion USD by 2025, which is likely to drive demand for EBPVD technologies. As manufacturers seek to innovate and improve product performance, the adoption of EBPVD processes is expected to rise, further propelling market growth.

Technological Advancements in EBPVD

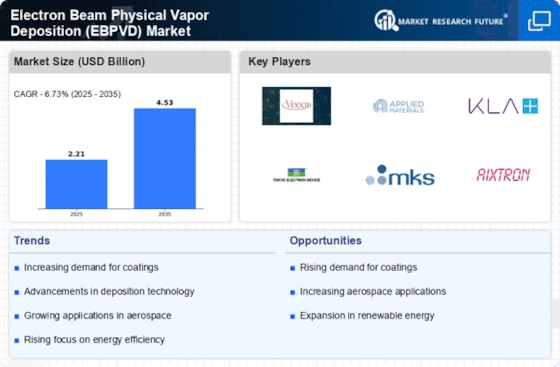

The Electron Beam Physical Vapor Deposition Market is experiencing a surge in technological advancements that enhance deposition processes. Innovations in electron beam technology, such as improved beam control and higher power densities, are enabling more precise and efficient coatings. These advancements are likely to reduce production costs and increase the quality of deposited films. Furthermore, the integration of automation and real-time monitoring systems is streamlining operations, thereby improving throughput. As a result, manufacturers are increasingly adopting EBPVD techniques to meet the growing demand for high-performance materials in sectors like aerospace and electronics. The market is projected to grow at a compound annual growth rate (CAGR) of approximately 6% over the next five years, driven by these technological improvements.

Rising Demand in Aerospace Applications

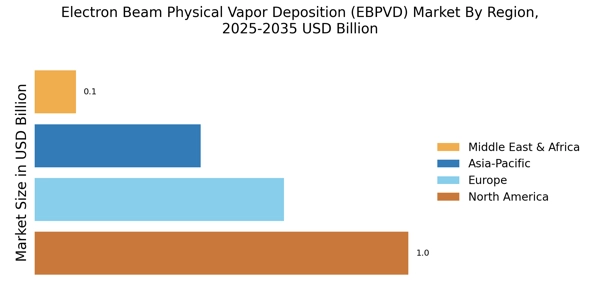

The demand for Electron Beam Physical Vapor Deposition Market (EBPVD) in aerospace applications is witnessing a notable increase. The aerospace sector requires advanced materials that can withstand extreme conditions, and EBPVD provides high-quality coatings that enhance durability and performance. The market for aerospace coatings is anticipated to grow significantly, with estimates suggesting a value of over 3 billion USD by 2026. EBPVD coatings are particularly favored for turbine blades and other critical components due to their superior thermal barrier properties. As the aerospace industry continues to expand, driven by increasing air travel and the need for fuel-efficient aircraft, the EBPVD Market is likely to benefit from this rising demand, positioning itself as a key player in the materials supply chain.

Emerging Applications in Renewable Energy

Emerging applications in renewable energy are poised to drive the Electron Beam Physical Vapor Deposition Market forward. As the world shifts towards sustainable energy solutions, EBPVD is being explored for its potential in producing high-efficiency solar cells and other renewable energy technologies. The ability to create thin, uniform coatings is particularly advantageous in enhancing the performance of photovoltaic cells. The renewable energy market is expected to grow at a CAGR of around 8% over the next five years, creating new opportunities for EBPVD applications. This trend suggests that as investments in renewable energy technologies increase, the EBPVD Market could see substantial growth, aligning with global energy transition goals.