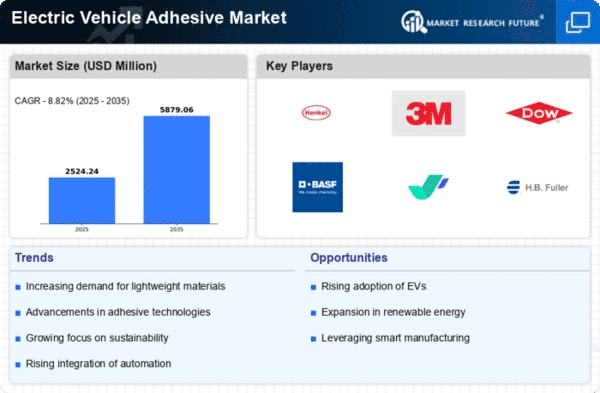

Market Growth Projections

The Global Electric Vehicle Adhesive Market Industry is projected to experience substantial growth in the coming years. With a market value of 2.32 USD Billion in 2024, it is expected to reach 5.88 USD Billion by 2035, reflecting a robust compound annual growth rate of 8.82% from 2025 to 2035. This growth trajectory indicates a strong demand for innovative adhesive solutions tailored for electric vehicles. Factors such as increasing electric vehicle production, advancements in adhesive technology, and supportive regulatory frameworks are likely to contribute to this upward trend, positioning the adhesive market as a vital component of the electric vehicle industry.

Growing Demand for Electric Vehicles

The increasing global demand for electric vehicles is a primary driver for the Global Electric Vehicle Adhesive Market Industry. As consumers and governments prioritize sustainable transportation, the adoption of electric vehicles is projected to rise significantly. In 2024, the market for electric vehicles is expected to reach 2.32 USD Billion, with projections indicating a growth to 5.88 USD Billion by 2035. This surge in electric vehicle production necessitates advanced adhesives that can withstand the unique challenges posed by electric vehicle design, such as lightweight materials and battery integration. Consequently, the demand for specialized adhesives is likely to increase, driving market growth.

Rising Consumer Awareness and Acceptance

Rising consumer awareness regarding environmental issues and the benefits of electric vehicles is driving the Global Electric Vehicle Adhesive Market Industry. As consumers become more informed about the advantages of electric vehicles, including lower emissions and reduced operating costs, the demand for these vehicles is expected to increase. This shift in consumer behavior is prompting manufacturers to invest in high-quality adhesives that enhance vehicle performance and safety. The growing acceptance of electric vehicles among consumers is likely to contribute to the overall growth of the adhesive market, as manufacturers seek to meet the rising expectations for quality and sustainability.

Regulatory Support for Sustainable Practices

Government regulations aimed at promoting sustainable practices are significantly influencing the Global Electric Vehicle Adhesive Market Industry. Many countries are implementing stringent emissions standards and providing incentives for electric vehicle adoption, which indirectly boosts the demand for electric vehicle adhesives. For example, regulations that encourage the use of lightweight materials in vehicle construction necessitate the use of specialized adhesives to ensure structural integrity. As regulatory frameworks continue to evolve, they are likely to create a favorable environment for the growth of the adhesive market, aligning with the broader goals of reducing carbon footprints and enhancing energy efficiency in transportation.

Technological Advancements in Adhesive Formulations

Innovations in adhesive formulations are enhancing the performance and applicability of adhesives in electric vehicles, thereby propelling the Global Electric Vehicle Adhesive Market Industry. Manufacturers are developing high-performance adhesives that offer superior bonding strength, thermal stability, and resistance to environmental factors. For instance, advancements in epoxy and polyurethane adhesives are enabling better integration of components, which is crucial for electric vehicle assembly. As these technologies evolve, they are expected to meet the increasing demands of electric vehicle manufacturers, further stimulating market growth. The anticipated compound annual growth rate of 8.82% from 2025 to 2035 underscores the potential impact of these innovations.

Expansion of Electric Vehicle Charging Infrastructure

The expansion of electric vehicle charging infrastructure is another critical driver for the Global Electric Vehicle Adhesive Market Industry. As more charging stations are established globally, the demand for electric vehicles is expected to rise, consequently increasing the need for adhesives in vehicle manufacturing. The integration of charging technology into vehicle designs requires robust adhesive solutions that can withstand various environmental conditions. This trend is likely to create new opportunities for adhesive manufacturers, as they develop products tailored to the evolving needs of electric vehicle manufacturers. The anticipated growth in the electric vehicle market will further bolster the adhesive market.