Increased Focus on Automation

The Conveyor Sprockets Market is witnessing a paradigm shift towards automation across various sectors. Industries are increasingly adopting automated solutions to enhance productivity and reduce operational costs. The automation market has been forecasted to grow at a CAGR of approximately 9% in the coming years, which is likely to have a direct impact on the demand for conveyor systems. As these systems become more prevalent, the need for reliable conveyor sprockets that can withstand high operational demands becomes critical. This shift towards automation not only improves efficiency but also necessitates the development of advanced sprocket designs that can accommodate varying speeds and loads. Therefore, the Conveyor Sprockets Market stands to benefit from this trend as manufacturers align their products with the requirements of automated systems.

Growth of E-commerce and Logistics

The Conveyor Sprockets Market is significantly influenced by the rapid growth of e-commerce and logistics sectors. As online shopping continues to gain traction, the demand for efficient warehousing and distribution systems has escalated. The logistics industry has been projected to grow at a CAGR of around 6% over the next few years, which is likely to drive the adoption of conveyor systems. These systems are essential for streamlining operations, reducing labor costs, and enhancing overall efficiency in warehouses. Consequently, the demand for conveyor sprockets, which are integral to these systems, is expected to rise. This trend indicates a robust opportunity for manufacturers within the Conveyor Sprockets Market to innovate and expand their product offerings to cater to the evolving needs of the logistics sector.

Rising Demand in Manufacturing Sector

The Conveyor Sprockets Market is experiencing a notable surge in demand, primarily driven by the expansion of the manufacturing sector. As industries increasingly automate their processes, the need for efficient material handling solutions becomes paramount. In recent years, the manufacturing sector has shown a compound annual growth rate (CAGR) of approximately 4.5%, which is expected to continue. This growth is likely to propel the demand for conveyor systems, thereby enhancing the need for high-quality conveyor sprockets. Furthermore, the integration of advanced technologies in manufacturing processes necessitates the use of reliable and durable conveyor components, including sprockets. Consequently, manufacturers are investing in innovative designs and materials to meet the evolving requirements of the Conveyor Sprockets Market.

Technological Innovations in Sprocket Design

The Conveyor Sprockets Market is significantly impacted by ongoing technological innovations in sprocket design and materials. Advances in engineering and materials science have led to the development of more durable and efficient sprockets that can withstand harsh operating conditions. Innovations such as the use of lightweight materials and enhanced tooth designs are becoming increasingly prevalent. These advancements not only improve the performance of conveyor systems but also reduce maintenance costs and downtime. The market for advanced materials is expected to grow, with projections indicating a CAGR of around 7% in the coming years. This trend suggests that manufacturers in the Conveyor Sprockets Market must continuously innovate to remain competitive and meet the evolving demands of their customers.

Emerging Markets and Infrastructure Development

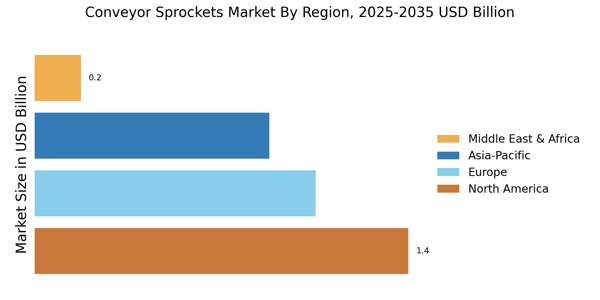

The Conveyor Sprockets Market is poised for growth due to the emergence of new markets and ongoing infrastructure development projects. Countries in Asia and Africa are investing heavily in infrastructure, which includes transportation and logistics systems. This investment is expected to drive the demand for conveyor systems, thereby increasing the need for conveyor sprockets. For instance, the construction of new airports, railways, and highways necessitates efficient material handling solutions. The infrastructure sector has been projected to grow at a CAGR of around 5% in the next few years, indicating a robust opportunity for the Conveyor Sprockets Market. Manufacturers are likely to capitalize on this trend by offering tailored solutions that meet the specific needs of these developing markets.