Growing Focus on Automation

Automation in semiconductor manufacturing is becoming increasingly prevalent, influencing the Chemical Mechanical Planarization Market. The integration of automated systems enhances production efficiency and reduces human error, which is critical in achieving the precision required in planarization processes. As companies strive to optimize their manufacturing lines, the market for automated Chemical Mechanical Planarization Market solutions is expected to expand significantly. In 2025, the automation segment within the semiconductor industry is anticipated to account for a substantial portion of the overall market, further driving the demand for advanced planarization technologies. This trend suggests that the Chemical Mechanical Planarization Market will continue to evolve, adapting to the needs of an increasingly automated manufacturing environment.

Emergence of Advanced Materials

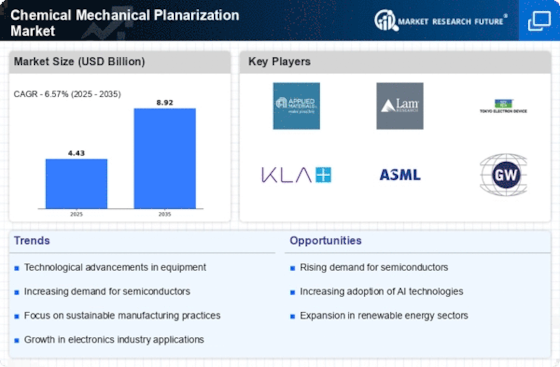

The introduction of new materials in semiconductor manufacturing is reshaping the Chemical Mechanical Planarization Market. Materials such as high-k dielectrics and low-k dielectrics require specialized planarization techniques to achieve the desired surface quality. The market is adapting to these changes, with an estimated growth rate of 7% annually in the planarization segment. This shift towards advanced materials is driven by the need for improved performance in electronic devices, which in turn fuels the demand for innovative Chemical Mechanical Planarization Market solutions. As manufacturers explore these new materials, the Chemical Mechanical Planarization Market is likely to see increased investment in research and development to create tailored solutions that meet the specific requirements of these advanced materials.

Increasing Semiconductor Production

The demand for semiconductor devices continues to rise, driven by advancements in technology and the proliferation of electronic devices. The Chemical Mechanical Planarization Market is experiencing growth as manufacturers seek efficient methods to produce high-quality wafers. In 2025, the semiconductor market is projected to reach approximately 600 billion USD, indicating a robust need for effective planarization techniques. This growth is largely attributed to the increasing complexity of semiconductor designs, which necessitate precise surface finishing to ensure optimal performance. As a result, the Chemical Mechanical Planarization Market is positioned to benefit from this upward trend, as companies invest in advanced planarization technologies to meet the escalating production demands.

Rising Demand for Consumer Electronics

The surge in consumer electronics, including smartphones, tablets, and wearables, is propelling the Chemical Mechanical Planarization Market forward. As these devices become more sophisticated, the need for high-performance semiconductors increases, necessitating advanced planarization techniques. The consumer electronics market is projected to reach over 1 trillion USD by 2025, creating a substantial demand for efficient manufacturing processes. This growth is likely to drive investments in Chemical Mechanical Planarization Market technologies, as manufacturers seek to enhance the quality and performance of their semiconductor components. Consequently, the Chemical Mechanical Planarization Market is expected to thrive in response to the escalating demand for cutting-edge consumer electronics.

Regulatory Compliance and Quality Standards

The Chemical Mechanical Planarization Market is also influenced by stringent regulatory compliance and quality standards in semiconductor manufacturing. As industries face increasing scrutiny regarding product quality and environmental impact, manufacturers are compelled to adopt advanced planarization techniques that meet these standards. Compliance with regulations not only ensures product reliability but also enhances the overall efficiency of manufacturing processes. The market is witnessing a shift towards sustainable practices, with an emphasis on reducing waste and improving energy efficiency. This trend is likely to drive innovation within the Chemical Mechanical Planarization Market, as companies invest in technologies that align with regulatory requirements while maintaining high-quality output.