Growth of the Automotive Aftermarket

The Automotive Stamping Market is also benefiting from the growth of the automotive aftermarket. As vehicle ownership rates rise, the demand for replacement parts and accessories is increasing. This trend is particularly pronounced in regions with aging vehicle fleets, where stamped components are essential for repairs and upgrades. The aftermarket segment is projected to grow at a rate of approximately 5% annually, providing a steady demand for stamped parts. Consequently, manufacturers in the Automotive Stamping Market are likely to expand their offerings to cater to this burgeoning market.

Increasing Electric Vehicle Production

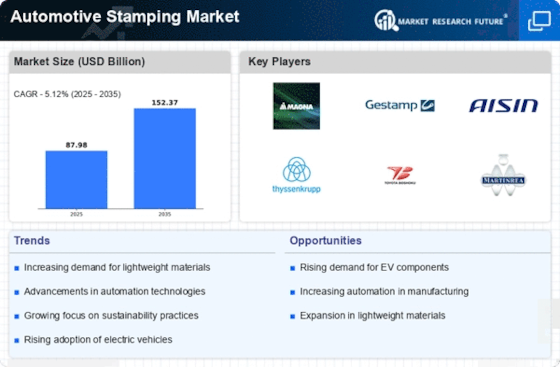

The shift towards electric vehicles (EVs) is significantly impacting the Automotive Stamping Market. As automakers ramp up production of EVs, the demand for specialized stamped components, such as battery enclosures and structural parts, is expected to rise. This transition is not only reshaping the types of materials used but also the stamping techniques employed. Industry forecasts suggest that the EV segment could account for over 30% of total automotive production by 2030, thereby creating substantial opportunities for growth within the Automotive Stamping Market.

Rising Demand for Lightweight Vehicles

The Automotive Stamping Market is experiencing a notable increase in demand for lightweight vehicles, driven by consumer preferences for fuel efficiency and lower emissions. Automakers are increasingly utilizing advanced stamping techniques to produce lighter components, which can significantly enhance vehicle performance. According to recent data, the market for lightweight materials in automotive applications is projected to grow at a compound annual growth rate of approximately 8% over the next five years. This trend is likely to propel the Automotive Stamping Market as manufacturers seek to innovate and adapt their production processes to meet these evolving demands.

Regulatory Pressure for Emission Reductions

Regulatory frameworks aimed at reducing vehicle emissions are exerting pressure on the Automotive Stamping Market. Governments worldwide are implementing stricter emissions standards, compelling manufacturers to adopt more efficient production methods and materials. This regulatory environment is likely to drive innovation in stamping technologies, as companies seek to comply with these regulations while maintaining profitability. The Automotive Stamping Market may see a shift towards more sustainable practices, with an anticipated increase in the use of recycled materials and eco-friendly processes.

Technological Advancements in Stamping Processes

Technological advancements are playing a crucial role in shaping the Automotive Stamping Market. Innovations such as high-speed stamping and precision tooling are enhancing production efficiency and reducing waste. The introduction of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems has streamlined the design and production phases, allowing for more complex geometries and improved quality control. As a result, manufacturers are likely to invest in these technologies to remain competitive, potentially leading to a market growth rate of around 6% annually in the coming years.