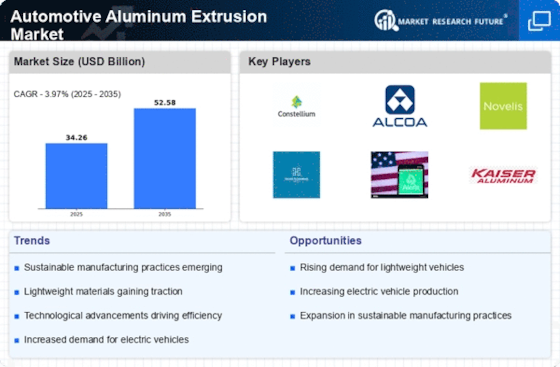

The Automotive Aluminum Extrusion Market is currently characterized by a dynamic competitive landscape, driven by increasing demand for lightweight materials that enhance fuel efficiency and reduce emissions in vehicles. Key players such as Constellium (France), Alcoa Corporation (US), and Novelis Inc. (US) are at the forefront, each adopting distinct strategies to solidify their market positions. Constellium (France) focuses on innovation in product development, particularly in high-strength aluminum alloys, which are essential for electric vehicle applications. Meanwhile, Alcoa Corporation (US) emphasizes sustainability, aiming to reduce its carbon footprint through advanced recycling technologies and energy-efficient production processes. Novelis Inc. (US) is strategically expanding its operations in Asia, capitalizing on the growing automotive market in that region, thereby enhancing its global footprint and operational efficiency.

The business tactics employed by these companies reflect a concerted effort to localize manufacturing and optimize supply chains. The market structure appears moderately fragmented, with several players vying for market share, yet the influence of major companies is substantial. This competitive environment is shaped by the collective actions of these key players, who are increasingly focusing on technological advancements and sustainable practices to differentiate themselves.

In August 2025, Constellium (France) announced a partnership with a leading electric vehicle manufacturer to supply advanced aluminum solutions tailored for battery enclosures. This strategic move not only reinforces Constellium's commitment to innovation but also positions the company as a critical supplier in the rapidly evolving electric vehicle sector. The partnership is likely to enhance Constellium's market presence and drive revenue growth in the coming years.

In September 2025, Alcoa Corporation (US) unveiled its new low-carbon aluminum production facility in the United States, which is expected to significantly reduce greenhouse gas emissions. This initiative aligns with global sustainability trends and positions Alcoa as a leader in environmentally responsible manufacturing. The facility's operational efficiency may also provide Alcoa with a competitive edge in pricing, appealing to environmentally conscious consumers and manufacturers alike.

In July 2025, Novelis Inc. (US) completed the acquisition of a regional aluminum extrusion company in Asia, which is anticipated to enhance its production capabilities and market reach. This acquisition not only strengthens Novelis's supply chain but also allows for greater responsiveness to local market demands. The strategic importance of this move lies in Novelis's ability to leverage synergies and optimize its operations in a key growth region.

As of October 2025, the competitive trends in the Automotive Aluminum Extrusion Market are increasingly defined by digitalization, sustainability, and the integration of artificial intelligence in manufacturing processes. Strategic alliances are becoming more prevalent, as companies recognize the need to collaborate to enhance innovation and efficiency. Looking ahead, the competitive differentiation in this market is likely to evolve from traditional price-based competition to a focus on technological advancements, sustainable practices, and supply chain reliability, reflecting the changing priorities of consumers and regulatory frameworks.

Leave a Comment