Top Industry Leaders in the Aromatic Ketone Polymer Market

Aromatic ketone polymers (AKPs) are a class of high-performance engineering plastics valued for their exceptional thermal stability, chemical resistance, and mechanical strength. These properties make them ideal for demanding applications in aerospace, automotive, medical, and electronics industries.

Aromatic ketone polymers (AKPs) are a class of high-performance engineering plastics valued for their exceptional thermal stability, chemical resistance, and mechanical strength. These properties make them ideal for demanding applications in aerospace, automotive, medical, and electronics industries.

Factors for Market Share:

-

Product Portfolio: Offering a diverse range of AKPs with varying properties like temperature resistance and chemical compatibility expands reach in different application segments. -

Technological Innovation: Continuous research and development of new AKP grades with improved performance and processing characteristics enhances competitiveness. -

Production Capacity and Cost Efficiency: Optimizing production processes and scaling up capacity helps maintain cost leadership and cater to growing demand. -

Global Distribution Network: A robust and reliable distribution network ensures timely delivery and customer satisfaction. -

Brand Recognition and Customer Service: Building a strong brand reputation and providing excellent technical support foster customer loyalty and market share.

Challenges and Opportunities:

-

High Price: AKPs are expensive compared to other engineering plastics, limiting their adoption in cost-sensitive applications. -

Complex Processing: AKPs require specialized equipment and expertise for fabrication, posing entry barriers for smaller players. -

Volatile Raw Material Costs: Fluctuations in the price of key monomers like benzophenone can impact AKP production costs and profitability.

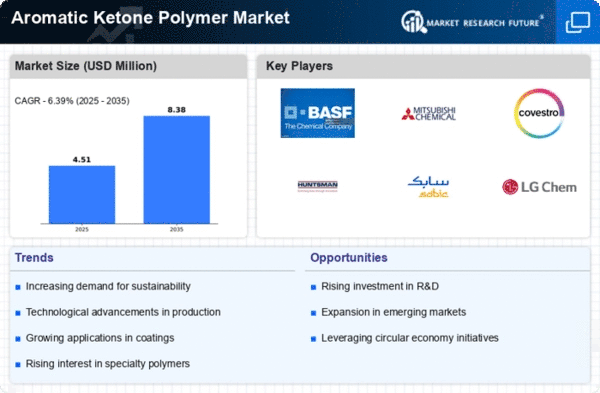

Key Players

- Victrex plc (UK),

- Solvay S.A.

- (Belgium),

- Evonik Industries (Germany),

- A.Schulman Inc (U.S.),

- DSM Engineering Plastics (Netherlands),

- EMS-CHEMIE HOLDING AG (Switzerland),

- Kuraray Co., Ltd (Japan),

- Gharda plastics (India),

- Darter Plastics (U.S.),

- Ismat (India),

Recent Developments :

-

August 2023: Solvay announces a new production facility for PEKK in China, aiming to capitalize on the region's growing demand for AKPs. -

September 2023: Victrex unveils a breakthrough PEEK resin with enhanced fire resistance, targeting applications in aircraft interiors and electrical components. -

October 2023: Evonik partners with a leading medical device manufacturer to develop PEEK-based spinal implants, expanding into the lucrative healthcare market. -

November 2023: Jinzhou Chemical secures a major supply contract with an European automotive OEM, marking a significant step towards establishing their PEEK brand globally. -

December 2023: Mitsubishi Chemical collaborates with a Japanese research institute to develop AKP composites with improved wear resistance for use in high-performance bearings.