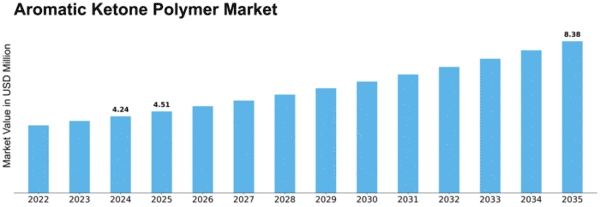

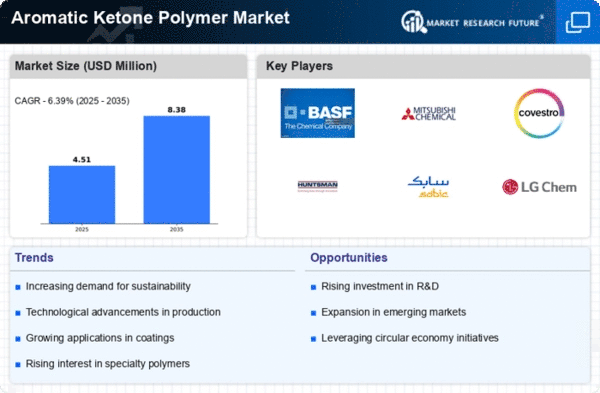

Aromatic Ketone Polymer Size

Aromatic Ketone Polymer Market Growth Projections and Opportunities

The Aromatic Ketone Polymer Market is influenced by various market factors that play a crucial role in shaping its dynamics. One significant factor is the increasing demand for lightweight and high-performance materials across industries such as aerospace, automotive, and electronics. Aromatic ketone polymers, known for their exceptional mechanical and thermal properties, are gaining popularity as they address the need for advanced materials in these sectors. The growing focus on fuel efficiency in the automotive industry and the need for durable, heat-resistant components in electronic devices are driving the market demand for aromatic ketone polymers.

Moreover, technological advancements and innovations in polymer production processes contribute to market growth. Continuous research and development efforts lead to the introduction of new and improved aromatic ketone polymer variants, expanding their applications and performance capabilities. Manufacturers are investing in cutting-edge technologies to enhance the production efficiency and quality of these polymers, thus meeting the evolving requirements of end-users.

Global economic conditions and geopolitical factors also significantly impact the aromatic ketone polymer market. Fluctuations in raw material prices, trade tensions, and economic uncertainties can affect the production costs and pricing strategies of manufacturers. Market players need to navigate these external factors strategically to maintain competitiveness and profitability in the dynamic business environment.

Environmental regulations and sustainability considerations are increasingly influencing the aromatic ketone polymer market. As the world moves towards eco-friendly and sustainable solutions, manufacturers are under pressure to develop environmentally responsible materials. Aromatic ketone polymers, with their potential for recyclability and energy efficiency during production, are aligning with the global push for sustainable practices. Companies that proactively adopt green initiatives are likely to gain a competitive edge in the market.

The Aromatic Ketone Polymer Market is also shaped by end-user industry trends. For instance, the aerospace industry's growing demand for lightweight materials to improve fuel efficiency and reduce emissions is a key driver for aromatic ketone polymers. Similarly, the electronics sector's need for high-performance materials that can withstand extreme temperatures and harsh environments further fuels the market growth. Understanding and adapting to these industry-specific trends are crucial for companies operating in the aromatic ketone polymer market to capitalize on emerging opportunities.

Market competition and the presence of alternative materials are additional factors that impact the aromatic ketone polymer market. As the industry evolves, new entrants may introduce innovative materials that compete with aromatic ketone polymers. Manufacturers need to stay vigilant and responsive to changing market dynamics, ensuring that their products remain competitive in terms of performance, cost, and sustainability.

The aromatic ketone polymer market is influenced by a combination of factors ranging from technological advancements and economic conditions to regulatory pressures and industry-specific trends. Navigating this complex landscape requires a strategic approach, with manufacturers focusing on innovation, sustainability, and responsiveness to market dynamics. As industries continue to seek high-performance materials with advanced properties, the aromatic ketone polymer market is poised for growth, provided that key market factors are effectively managed and leveraged.

Leave a Comment