Market Analysis

In-depth Analysis of Aluminum Aerosol Cans Market Industry Landscape

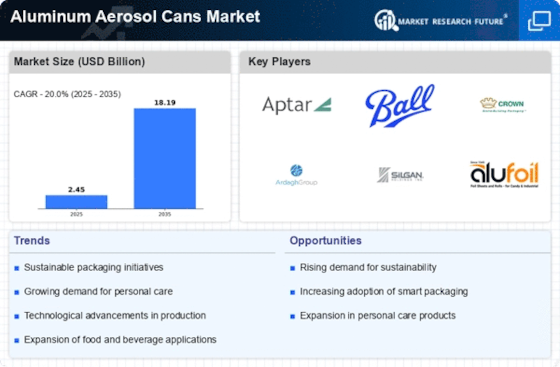

The market dynamics of aluminum aerosol cans are shaped by a combination of factors influencing supply, demand, and overall industry trends. As an essential component in the packaging sector, aluminum aerosol cans find widespread applications in various consumer products, ranging from personal care items to household products and pharmaceuticals. Understanding the market dynamics involves examining key elements such as consumer preferences, regulatory influences, economic conditions, technological advancements, and competitive forces.

One significant factor driving the market dynamics is the increasing emphasis on sustainability and eco-friendly packaging solutions. Aluminum aerosol cans, being lightweight, durable, and fully recyclable, align with the global shift towards reducing plastic usage and minimizing environmental impact. Consumers, becoming more environmentally conscious, are increasingly choosing products packaged in aluminum aerosol cans, leading to a surge in demand. Manufacturers are responding by investing in sustainable practices, incorporating recycled materials, and adopting eco-friendly manufacturing processes.

Regulatory influences play a pivotal role in shaping the market dynamics of aluminum aerosol cans. Governments worldwide are implementing measures to reduce environmental impact, and regulations often mandate the use of recyclable materials in packaging. Compliance with these regulations is crucial for manufacturers to maintain market access and meet the expectations of environmentally conscious consumers. The need for continuous adherence to evolving standards requires companies to invest in research and development to improve the sustainability and recyclability of their aluminum aerosol cans.

Economic conditions, including raw material prices and overall economic stability, contribute to the market dynamics of aluminum aerosol cans. The production of these cans relies on aluminum, and fluctuations in aluminum prices can impact manufacturing costs. Economic downturns may also influence consumer spending patterns, affecting the demand for products packaged in aluminum aerosol cans. Manufacturers must navigate these economic factors to remain competitive, balancing cost considerations with the demand for sustainable packaging solutions.

Technological advancements in manufacturing processes and design significantly impact the market dynamics of aluminum aerosol cans. Innovations aimed at improving the efficiency of production, enhancing product aesthetics, and incorporating user-friendly features contribute to the evolution of the market. Companies investing in advanced technologies can gain a competitive edge by offering high-quality, visually appealing, and functional aluminum aerosol cans, meeting the demands of both consumers and brands seeking innovative packaging solutions.

Challenges within the market dynamics include intense competition among manufacturers, pricing pressures, and supply chain complexities. The aluminum aerosol can market is characterized by a diverse range of companies vying for market share, leading to competitive pressures. Manufacturers need to differentiate themselves through product quality, design, and cost-effectiveness. Balancing affordability with sustainability becomes essential in the face of pricing pressures, while managing the intricacies of the supply chain, including aluminum sourcing and production timelines, presents additional challenges.

Global considerations, such as trade dynamics, supply chain logistics, and geopolitical factors, also influence the market for aluminum aerosol cans. Manufacturers may need to navigate trade agreements, tariffs, and logistical challenges to ensure seamless product flow across international borders. Adapting to geopolitical shifts and understanding market dynamics in different regions becomes crucial for sustained success in the global aluminum aerosol can market.

Leave a Comment