Growth in Aircraft Production

The Aircraft Gears Market is poised for growth due to the rising production rates of commercial and military aircraft. As air travel demand continues to rebound, manufacturers are ramping up production to meet this need. The International Air Transport Association projects a steady increase in passenger numbers, which necessitates the production of new aircraft equipped with advanced gear systems. This growth in aircraft production directly correlates with the demand for high-performance gears, as they are essential components in ensuring the reliability and efficiency of modern aircraft. Consequently, the Aircraft Gears Market is likely to benefit from this upward trend.

Increasing Demand for Fuel Efficiency

The Aircraft Gears Market is experiencing a notable surge in demand for fuel-efficient aircraft. Airlines are increasingly seeking to reduce operational costs, and fuel efficiency plays a pivotal role in this endeavor. Advanced gear systems contribute to improved aerodynamics and reduced weight, which in turn enhances fuel economy. According to recent data, the aviation sector aims to achieve a 50% reduction in carbon emissions by 2050, driving the need for innovative gear solutions. This trend is likely to propel the Aircraft Gears Market as manufacturers focus on developing lightweight and efficient gear systems that align with these sustainability goals.

Technological Innovations in Gear Design

Technological advancements are reshaping the Aircraft Gears Market, with innovations in gear design and materials leading to enhanced performance. The introduction of advanced composite materials and precision engineering techniques allows for the creation of gears that are not only lighter but also more durable. These innovations are crucial as they contribute to the overall efficiency and safety of aircraft operations. Furthermore, the integration of computer-aided design (CAD) and simulation technologies enables manufacturers to optimize gear performance, thereby meeting the stringent requirements of modern aviation. As these technologies continue to evolve, the Aircraft Gears Market is expected to witness significant advancements.

Regulatory Compliance and Safety Standards

The Aircraft Gears Market is significantly influenced by stringent regulatory compliance and safety standards imposed by aviation authorities. These regulations necessitate the use of high-quality materials and manufacturing processes to ensure the reliability and safety of aircraft components. As safety remains a top priority in aviation, manufacturers are compelled to invest in advanced gear technologies that meet or exceed these standards. This focus on compliance not only enhances the safety of aircraft operations but also drives innovation within the Aircraft Gears Market. Consequently, adherence to regulatory requirements is likely to foster growth and development in this sector.

Expansion of Aerospace Manufacturing Capabilities

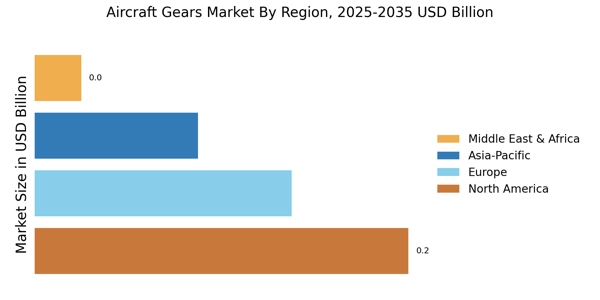

The Aircraft Gears Market is benefiting from the expansion of aerospace manufacturing capabilities across various regions. As countries invest in their aerospace sectors, the establishment of new manufacturing facilities and partnerships is becoming increasingly common. This expansion allows for localized production of aircraft gears, reducing lead times and transportation costs. Moreover, the growth of small and medium-sized enterprises in the aerospace sector is fostering competition and innovation, leading to the development of specialized gear solutions. As these manufacturing capabilities continue to grow, the Aircraft Gears Market is expected to experience enhanced supply chain efficiencies and increased market participation.