Top Industry Leaders in the Aircraft Fairings Market

The integration of smart materials and sensors is another noteworthy trend, enabling real-time monitoring of fairing conditions and facilitating predictive maintenance strategies. As the industry continues to prioritize sustainability and operational efficiency, these innovations in aircraft fairings are playing a pivotal role in shaping the future of aviation.

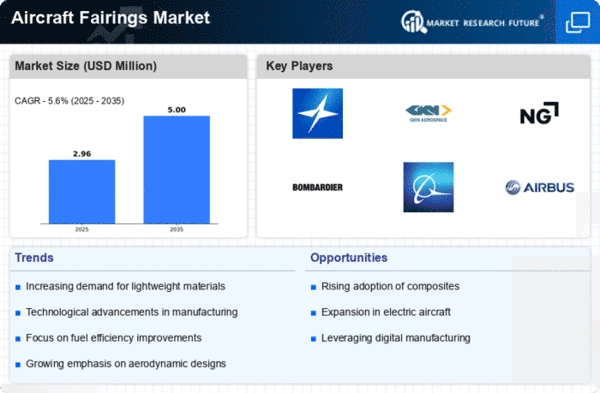

Key players :

FACC AG (Austria)

ShinMaywa Industries, Ltd. (Japan)

Strata Manufacturing (UAE)

Malibu Aerospace LLC. (US)

DAHER (France)

Airbus S.A.S. (Netherlands)

Boeing (US)

CTRM Sdn. Bhd. (Malaysia)

The NORDAM Group LLC (US)

AAR (US)

Strategies Adopted

Strategies adopted by key players also include a strong emphasis on research and development to stay ahead of the technological curve. With a focus on developing advanced materials and manufacturing techniques, these companies are ensuring that their fairings meet the ever-evolving demands of the aviation industry. Daher, in particular, has been investing in innovative manufacturing processes to enhance the performance and durability of its fairings.

The factors influencing market share analysis in the Aircraft Fairings Market are multifaceted. The growing emphasis on fuel efficiency and reduced carbon emissions is a major driver, compelling airlines and aircraft manufacturers to invest in aerodynamic solutions like advanced fairings. Additionally, the increasing air traffic and a surge in demand for new-generation aircraft contribute to the market's expansion. The market share is also influenced by the geographic presence of key players, their product portfolios, and their ability to cater to a diverse range of aircraft types.

Emerging Companies

the Aircraft Fairings Market. Companies like ShinMaywa Industries Ltd. (Japan) and Malibu Aerospace LLC (U.S.) are gaining recognition for their innovative approaches and niche offerings. ShinMaywa Industries has been focusing on the development of amphibious aircraft, and its fairings are integral to achieving optimal aerodynamics during both air and water operations. Malibu Aerospace, on the other hand, has been specializing in aftermarket fairings, providing cost-effective solutions for aircraft upgrades and modifications.

Industry news in the Aircraft Fairings Market reflects the dynamic nature of the aviation sector. Recent developments include collaborations between fairing manufacturers and aircraft OEMs to ensure seamless integration of these components. Additionally, advancements in materials science, such as the use of advanced composites, are making headlines as they contribute to the development of lighter and more durable fairings. The market is also witnessing a surge in demand for customizable fairings, allowing airlines to tailor these components to specific aircraft models and operational requirements.

Current company investment trends in the Aircraft Fairings Market indicate a strong focus on sustainability and technological innovation. Investments in research and development activities are prevalent, as companies strive to stay ahead in a rapidly evolving industry. Moreover, strategic partnerships and collaborations are on the rise, enabling companies to pool resources and expertise for mutual benefit. Investment trends also reflect a growing interest in digital technologies, with companies exploring the integration of smart materials and sensors in fairing design for enhanced performance monitoring and maintenance.

Recent News

In March 2023, Travis Airforce Base joined forces with Engineering and Engineering Support contractors to enhance the aerodynamic fairing of a C-5M Super Galaxy, incorporating innovative 3D printed components. The USAF Rapid Sustainment Office played a pivotal role by providing printed blocks and wedges to support the C-5 hump panel, ensuring optimal aerodynamics over the wing. The base opted for Antero 800NA, a thermoplastic material, for the 3D printing of replacement parts for the aircraft.

Moving to January 2023, the BEAMIT Group in Italy inked a significant five-year production agreement with Leonardo, a key aerospace player in Italy. This collaboration saw the integration of over 100 parts manufactured by BEAMIT into Leonardo's crucial aircraft models, including the M345, M346, and C27J. The agreement not only facilitated the incorporation of advanced components but also marked a commitment to joint efforts in developing and standardizing additive manufacturing processes